Microbial Control by Physical Methods

| Home | | Pharmaceutical Microbiology | | Pharmaceutical Microbiology |Chapter: Pharmaceutical Microbiology : Microbial Control by Physical and Chemical Methods

The physical methods related to microbial control (or growth) are as enumerated under : (a) Heat, (b) Moist Heat, (c) Pasteurization, (d) Dry-Heat Sterilization, (e) Filtration, (f) Cold, (g) Desiccation, (h) Osmotic Pressure, and (i) Radiation.

PHYSICAL

METHODS

The physical methods related to microbial control (or growth) are as

enumerated under :

(a) Heat,

(b) Moist

Heat,

(c) Pasteurization,

(d) Dry-Heat

Sterilization,

(e) Filtration,

(f) Cold,

(g) Desiccation,

(h) Osmotic

Pressure, and

(i) Radiation.

All these

individual methods shall now be treated separately in the sections that follows

:

(a). Heat

Heat represents probably the most

common effective, and productive means whereby organisms are almost killed. In fact, it is a usual practice to have the

laboratory media, laboratory glasswares, and hospital surgical instruments

adequately sterilized by heat i.e.,

moist heat in an electric autoclave.

Salient Features. Following

are the salient features of heat

controlled microbes, namely :

(1) Most

economical and easily controlable means of microbial growth.

(2) Usually

kill microbes by causing denaturation of their respective enzymes.

(3) Heat

resistance capacity of the organism must be studied carefully and taken into

consideration.

(4) Thermal Death Time (TDT). TDT is

referred to as the minimal length of time whereby all microbes present in a liquid culture medium will be killed at a

given temperature.

(5) Thermal Death Point (TDP). TDP designates

the lowest temperature at which all

of the microorganisms present in a

liquid suspension will be killed in just 10 minutes. In fact, heat resistance

predominantly varies amongst the different range of organisms ; besides, these

glaring differences may be duly expressed via

the concept of thermal death point

(TDP).

However,

it is pertinent to state here that both TDP and TDT are equally vital,

important, and useful guidelines which essentially indicate the actual

prevailing severity of treatment needed to kill

a given population of organisms.

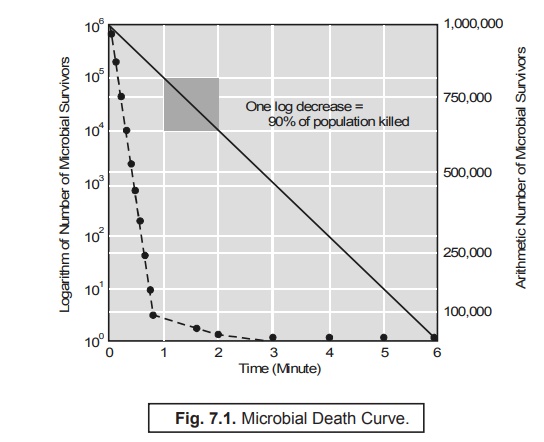

(6) Decimal Reduction Time [DRT or D-Value]. DRT or D-Value represents a 3rd concept which is directly associated with the organism’s extent of heat resistance. In fact, it is very much

equivalent to the time (minutes), whereby almost 90% of the population of

prevailing microbes at an exact specified temperature shall be killed as

illustrated in Fig. 7.1, having DRT of 1 minute. It is, however, pertinent to

mention here that DRT is of an extreme importance and usefulness in the ‘canning industry’ dealing with fruit

concentrates, fruit pulps, fruit slices, baked beans, corned-beef, fish products, fish chuncks, baby

corns, lentils, and the like.

[Redrawn

From : Tortora GJ et. al. : Microbiology : An introduction., The

Benjamin/Cummings Pub. Co. Inc. New York, 5th edn., 1995].

The curve

in Fig. 7.1 is plotted logarithmically

(as shown by solid line), and arithmatically (as shown by broken line). In this particular

instance, the microbial cells are

found to be dying at a rate of 90% min–1.

b. Moist Heat

It is a

common practice to make use of ‘heat’

in the process of sterilization either in the form of ‘moist heat’ or ‘dry heat’.

It has

been duly proved and established that the so called ‘moist heat’ invariably kills microbes at the very first instance

by the process known as ‘coagulation of

proteins’, that is eventually caused by the specific cleavage of the H-bonds which critically retain the protein in its 3D-structure*. Interest-ingly, one may visualize the phenomenon of protein coagulation/denaturation rather

more vividly in the presence of water.

‘Moist heat’ sterilization may be achieved

effectively by the following widely accepted known methods, such as :

(a) Boiling,

(b) Autoclaving,

and

(c) Pasteurization.

Each of

the aforesaid method of moist-heat

sterilization shall now be treated individually in the sections that

follows :

(a) Boiling

Boiling at 100°C at 760 mm atmospheric

pressure is found to kill particularly several varieties of vegetative states of microbial strains, a good number of viruses

and fungi ; besides their ‘spores’

within a span of 10 minutes only. It is quite obvious that the ‘unpressurized’ i.e., free-flowing steam

is practically equivalent to the prevalent temperature of boiling water (i.e., 100°C). It has been revealed that

the endospores plus certain viruses are evidently not destroyed in

such a short duration of 10 minutes.

Examples.

(a) A typical hepatitis virus may even survive upto a duration of 30 minutes of continuous boiling at an atmospheric

pressure.

(b) Likewise,

there are certain microbial endospores

that have been offered resistance to boiling for more than 30 hours.

Conclusion. Boiling for a couple of minutes

will certainly kill organisms present in a Baby’s Feeding Bottle + Nipple, food products, drinking water relatively

safer for human consumption.

(b) Autoclaving

The most

reliable sterilization with moist heat

prominently requires such ranges of temperature that are critically above the boiling water i.e., above 100°C. These

high temperatures [120 ± 2°C] are

most conveniently accomplished by moist steam under positive pressure usually

in an ‘autoclave’. One may make use

of ‘autoclaving’ as a means of

sterilization unless the drug substance or material to be sterilized can suffer

serious type of damage either by heat

or by moisture. In fact, higher the

pressure inside the autoclave, the higher will be the temperature inside the

autoclave.

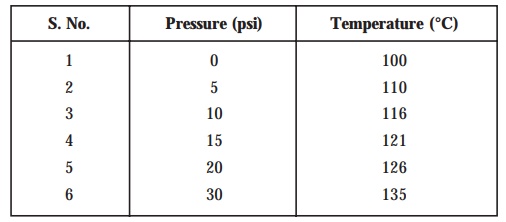

Examples. The following are two typical sets of examples viz.,

(a) Relationship between pressure and temperature

of steam at sea level. It has been adequately proved that—‘the higher the pressure created inside the

autoclave, the higher would be the

attainable temperature inside the autoclave’.

When the

free-flowing stream at a prevailing temperature of 100°C is subjected under

pressure of 1 atmosphere above the sea-level pressure i.e., 15 pounds pressure per square inch (psi), the tempera-ture

inside the autoclave happens to rise upto 121°C, which is an usual and common

parameters em-ployed in the sterilization of food products and surgical

instruments. One may also work at relatively lower/higher pressure (psi) vis-a-vis lower/higher temperatures (°C)

as clearly given in Table : 7.1.

Table 7.1. Relationship Between Pressure and

Temperature of Steam at Sea Level*

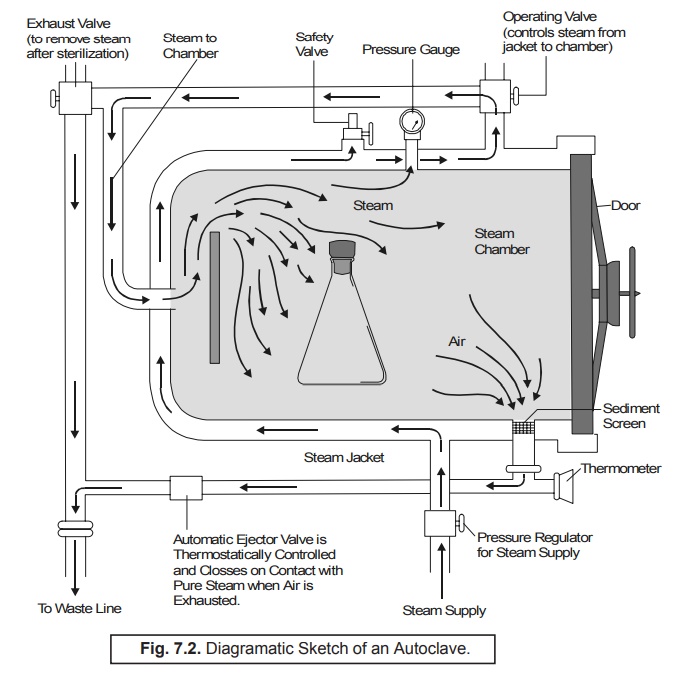

Figure

7.2 illustrates the beautiful elaborated diagramatic representation of an

autoclave.

In a

broader perspective, ‘sterilization’

in an autoclave is considered to be

most effective par-ticularly in a situation when the microbes either contact

the steam directly or are adequately contained in a small volume of aqueous

(mostly water) liquid. Importantly, under such a critical experimental

param-eters (i.e., steam at a

pressure of 15 psi at 121°C) all the microbes would be killed while their

endospores in almost within a span of 15 minutes.

Applications of an Autoclave. The

various applications of an autoclave are as enumerated under :

(1) To

sterilize culture media for the identification and propagation of pure strains

of microor-ganisms and yeasts.

(2) To

sterilize various surgical stainless steel instruments that are required for

most of the sur-gical procedures, dental procedures, obstretrics etc.

(3) To

sterilize various types of surgical dressings, gauzes, sutures etc.

(4) To

sterilize a host of IV applicators, equipments, solutions, and syringes as

well.

(5) To

sterilize transfusion equipment(s) and a large number of other alied items that

can con-veniently withstand high pressures and temperatures.

(6) When

the ‘large industrial premises’ make use of the autoclaves, these are knwon as re-torts,

whereas, the small domestic applications invariably employ pressure cookers (both based

on exactly the same principles) for

preparation of food* and canning of processed food products.

Important Aspects. In a

situation, when we essentially look for

extended heat requirement so as

to specifically reach the exact centre

of the solid materials viz.,

canned meats, fish (tuna), due to the fact that such materials fail miserably

to develop the most desired efficient

convection currents which invariably take place in the body of liquids.

Therefore,

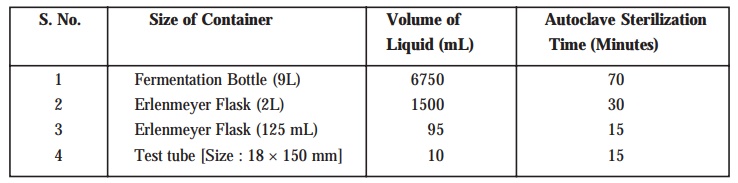

the particular heating of large containers/vessels does essentially require

extra time period (in minutes) as given in Table 7.2.

Table 7.2. Overall Effect of Container Size upon

Autoclave Sterilization Times (Minutes) for Liquid Solutions**.

(i) The autoclave sterilization times in

the autoclave very much include the time required for the contents of the

containers to perfectly reach the sterilization temperatures.

(ii) Obviously,

for a very small container this is only 5 minutes or even less, whereas for a 9

L capacity fermentation bottle it might be as high as ~ 70 minutes.

(iii) All

containers that are supposed to be sterilized by ‘autoclave’ are invariably filled only upto 3/4th the total volume i.e., their actual capacity.

Salient Features. The salient features of ‘autoclave sterilization’ are briefly

stipulated as under :

(1) In

order to sterilize duly the surface of a solid, one must allow the ‘steam’ to actually contact the same.

Nevertheless, particular care must be taken to allow the perfect sterilization

of bandages, dry-glasswares, and the like so as to ascertain that steam gets

into contact with all the exposed surfaces.

Example. Aluminium foil does not

allow the passage of steam to pass across (i.e., impervious), and hence must be avoided to wrap such materials meant to be

sterilized ; instead, one may freely make use of brown wrapping paper (cellulose).

(2) Trapped Air. All necessary precautions and

requisite care must be taken to get rid of any trapped air strategically located at the bottom of a ‘dry container’, due to the fact that

the ‘trapped air’ shall not be

replaced by ‘steam’ at any cost,

which being lighter than air. However, one may just visual-ize imaginatively

the so called ‘trapped air’ as a mini-hot air oven, that would eventually

require not only a higher temperature

but also a much longer duration to sterilize materials.

Based on

the actual experience one may specifically tackle such containers which have a

ten-dency to trap air must be

positioned in a ‘tipped state’ in

order that all the steam shall ultimately help to force out the air.

Note. Importantly, such products which obstruct

penetration by moisture viz., petroleum jelly, mineral oil (furnace oil) are

not usually sterilized by the same methods as adopted to sterilize aqueous

solutions.

(c) Pasteurization

Pasteurization refers to ‘the process of heating of a fluid at a moderate temperature for a

definite period of time to destroy undesirable microorganisms without changing

to any extent the chemical composition.’

Example. In pasteurization of milk,

pathogenic organisms are invariably destroyed by heating at 62° C for a duration of 30 minutes, or by ‘flash’ heating to higher temperatures for less than 1 minute,

which is otherwise known as high-temperature

short time (HTST) pasteurization.

In a

broader perspective the pasteurization of milk, effectively lowers the total

bacterial count of the milk by almost 97 to 99%, due to the fact that the most

prevalent milk-borne pathogens viz.,

Tubercle bacillus*, and Samonella, Streptococcus, and Brucella organisms,

fail to form ‘spores’, and are quite sensitive

to heat.

It may,

however, be observed that several relatively heat-resistant (thermoluric) microorganisms do survive

pasteurization, and these may

ultimately fail to :

·

Cause refrigerated milk to turn sour (spoil) in a

short span of time, and

·

Cause any sort of disease in humans.

Ultra-High-Temperature (UHT) Treatments. Sterilization

of milk is absolutely different from pasteurization.

It may be duly accomplished by UHT

treatments in order that it can be most easily and conveniently stored even

without any sort of refrigeration. So as to maintain the first order ‘organoleptic characteristic features’** of fresh milk and to avoid attributing

to the milk a prevalent cooked taste, the

UHT system gained reasonable

qualified success and hence due recognition across the globe, whereby the

liquid milk never touches a surface hotter than the milk itself during the

course of heating by steam.

Methodology. The various steps involved are as

follows :

(1) Milk

is allowed to fall in a thin-film

vertically down through a stainless-steel (SS) chamber of ‘superheated steam’, and attains 140°C in less than 1 second.

(2) Resulting

milk is adequately held for a duration of only 3 seconds duly in a ‘holding

tube’.

(3) Ultimately,

the pre-heated milk is cooled in a ‘vacuum

chamber’, wherein the steam simply flashes

off.

(4) The

above stated process [(in (3)] distinctly enables the milk to raise its

temperature from 74—140°C in just 5 seconds, and suddenly drops back to 74°C

again.

Summararily,

the very concept of equivalent

treatments* clearly expatiates the particular rea-sons of the various

methods of killing microbes, such as :

Pasteurization : At 63°C for 30 minutes ;

HTST-Treatment : At 72°C for 15 seconds ;

UHT-Treatment : At 140°C for < 1 second ;

(d) Dry-Heat Sterilization

It is a

well known fact that microorgansims get killed by dry heat due to the oxidation effects.

Direct Flaming. Direct flaming designates

one of the most simple method of

dry-heat sterili-zation. In reality, the dry-heat sterilization is mostly

used in a ‘microbiology laboratory’ for

the steri-lization of the ‘inoculating

loops’, which is duly accomplished by heating the loop wire to a ‘red-glow’, and this is 100% effective

in actual practice. Likewise, the same principle is even extended to the process of ‘inceneration’ to sterilize as well as dispose of heavily

contaminated paper bags, cups, and used dressings.

Hot-Air Sterilization. It may be

regarded as another kind of dry-heat

sterilization. In this particular

process, the various items need to be sterilized are duly kept in an electric oven, preferably with a

stainless-steel chamber inside, and duly maintained at 170°C for a duration of

approximately 2 hours (to ensure complete sterilization).

It has

been adequately observed that the longer

the period plus higher temperature

are needed profusely due to the fact that the heat in water is more rapidly passed onto a ‘cool body’ in comparison to the heat in air.

Example. The experience of exposing the ‘finger’ in a boiling water at 100°C (212°F) vis-a-vis exposing the

same ‘finger’ in a hot-air oven at

the same tempearture for the same

duration.

(e) Filtration

Filtration may be defined as ‘the process of removing particles from a

solution by allowing the liquid position to pass through a membrane or other

particle barrier’. In reality, it essentially contains tiny spaces or holes which exclusively allow the liquid

to pass but are too small to permit the passage of the small particles.

In other

words, one may also explain ‘filtration’

as the process of a liquid or gaseous substance via a screen-like material having suitable pores small enough to

retain the microorganisms (bacteria). A vacuum

which is formed in the ‘receiver flask’

actually aids by means of gravity to suck the liquid via the filter medium engaged. However, in actual practice the

phenomenon of filtration is

invariably em-ployed to sterilize the specific

heat sensitive substances, namely : culture

media ; vaccines ; enzymes ; and several

antibiotic solutions.

High-Efficiency Particulate Air (HEPA) Filters.

HEPA-Filters are mostly used to get rid of practically all microbes that happen to be larger than 0.3 μm in

diameter.

Examples. HEPA-Filters are

largely used in :

(a) Intensive-Care Units [ICUs] in

specialized hospitals treating severe Burn

cases.

(b) In Sterile Zones of

High-Value Antibiotic Preparations, Packaging, IV-injections, and other such

sensitive sterile preparations.

Membrane Filters. In the

recent past, technologically advanced

membrane filters made up of either

Cellulose Esters or Plastic Polymers have been employed

profusely for the laboratory and industrial applications as shown in

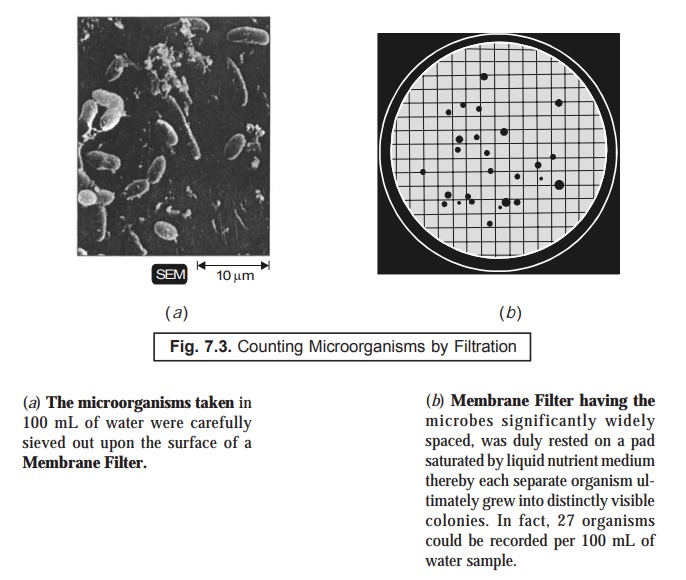

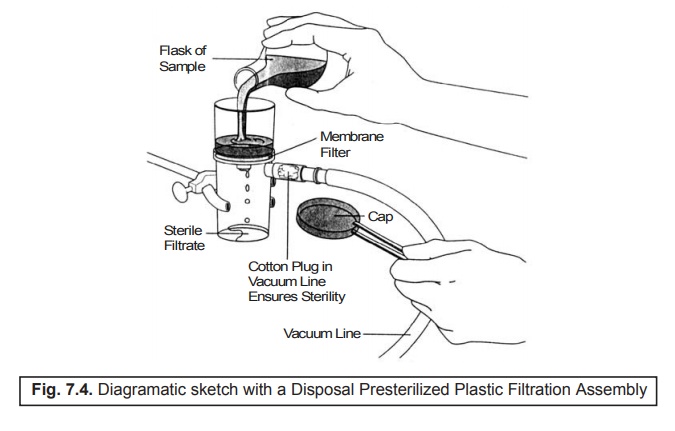

Fig. 7.3 and 7.4.

Explanation for Fig. 7.4 :

(1) The

sample to be filtered is duly loaded into the ‘upper chamber’, and consequently forced through the strategically

placed membrane filter.

(2) The

pores present in the membrane filter

are definitely much smaller in comparison to the microorganisms ; and,

therefore, the microorganisms present are obviously retained upon the surface

of the filter.

(3) Sterilized

sample (free from microbes) may now be decanted conveniently from the ‘lower chamber’.

Specifications of Membrane Filters. Membrane

filters usually have a thickness of 0.1 μm, and having almost uniform pores. However, in certain commercially available brands, the film

is duly irradiated so as to generate

extremely uniform holes, where the radiation particles have made its passage, are critically etched in the

plastic. The pores of membrane filters usually range between 0.22 to 0.45 μm, intended for microorganisms.

Note. (1) Certain highly flexible microbes viz. spirochaetes, and the wall-less

bacteria viz., mycoplasma, may sometimes pass through such membrane filters.

(2) To retain certain viruses and large-sized

protein molecules are duly retained by such filters with pore size as small as

0.01 μm.

(f) Cold

It has

been critically observed that the overall effect of ‘low temperature’ upon the microorgan-isms exclusively depends on

the specific organism and the intensity of the application.

Example. At temperatures ranging between

0–7°C (i.e., the ordinary refrigerator), the actual rate of metabolism of

majority of microorganisms gets reduced substantially to such an extent that

they are rendered incapable of either

synthesizing toxins* or causing reproduction.**

Thus, one

may conclude that ‘ordinary

refrigeration’ exerts a distinct bacteriostatic

effect i.e., stops the

multiplication vis-a-vis growth of

microbes.

Psychotrophs***, however, are found to grow

appreciably but slowly particularly at the

refrigerator temperature conditions ; and may change the very appearance and taste of food products after a certain lapse of time.

Salient Features. The

various salient features of microbes

in a ‘cold’ environment are as

follows :

(1) A few

microbes may even grow at sub-freezing

temperatures (i.e., below the

freezing temperature).

(2) Sudden

exposure to sub-freezing temperatures

invariably render bacteria into the ‘dormant-state’;

however, they do not kill them (bactericidal effect) ultimately.

(3) Gradual Freezing is

observed to be quite harmful and detrimental to microorganisms, per-haps due to

the fact that the ice-crystals which eventually form and grow do disrupt the cellu-lar as well as the molecular structure of the

microorganisms.

(4) Life-Span of Frozen Vegetative Microbes—Usually

remain active for a year upto 33% of the

entire initial population, whereas

other microbial species may afford relatively very scanty survival rates.

(g) Desiccation

In order

to have both normal growth and adequate multiplication the

microorganisms do re-quire water.

Desiccation represents a typical state of microbes in the absence of water ; however, their growth and

reproduction remain restricted but could sustain viability for several years.

Interestingly, as soon as ‘water’ is

duly made available to them the said organisms resume their usual growth and

divi-sion as well. This highly specific ability has been adequately employed in

the laboratory manipulations whereby the microbes are carefully preserved by lyophilization.*

It has

been duly observed that the ensuing resistance of the vegetative cells to

undergo the phenomenon of desiccation changes with the specific species as well as the microorganism’s environment.

Example : Gonorrhea** organism, Neisseria

gonorrhoeae (Gonococcus), possess

an ability to withstand dryness only

upto a duration 60 minutes hardly ; whereas, Tuberculosis*** bacterium, Mycobacterium

tuberculosis (Bacillus) may even

remain completely viable for months together at a stretch.

Important Points : Following

are certain important points which should always be borne in mind :

(a) An

invariably susceptible microbe is found to be appreciably resistant when it

gets duly embedded in pus cells, mucous secretions, and in faeces.

(b) In

contract to microbes the viruses are usually found to be quite resistant to the

phenomenon of ‘desiccation; however, they do not exhibit resistance comparable

to the bacterial endospores.

(c) Importantly,

in a typical hospital environment (setting) the presence and subsequent ability

of some particular dried bacteria and endospores do remain absolutely viable,

such as : beddings, clothings, dust particulate matters, and above all the

disposable (used) dressings from patients may contain infectious organisms

strategically located in dried pus, faecal matter, mucous secretions, and

urine.

(h) Osmotic Pressure

Osmotic pressure refers to–‘the pressure which develops when two solutions of different

concentrations are duly separated by a semipermeable membrane’.

In actual

age-old practice, the preservation of food products viz., pickles, fruits, are duly accom-plished by the use of

high-concentrations of salts and sugars which eventually exert their

effects on account of the osmotic

pressure. The most logical and probable underlying mechanism being the

creation of an extremely hypertonic environment due to the presence of these substances

(salts and sugars) at high concentrations that enables water to leave the microbial cell precisely. In fact, the

preservation afforded by the osmotic

pressure very much resembles to that caused by desiccation (see Section 7.2.2.7), besides, the glaring fact that

both processes evidently deny the

microbial cell of the requisite quantum of moisture essentially required

for its normal growth. Dehydration of the microbial

cell actu-ally renders the plasma

membrane to shrink away from the

respective cell-wall (i.e.,plasmolysis), whereby the consequent

cell stops growth (and hence reproduction), and it may not cause an instant

death. In a broader perspective, the fundamental principle of osmotic pressure is largely exploited

in the prolonged preservation of food products.

Examples : (a) Concentrated Salt

Solutions (Brine Solution) may be used profusely in the preservation and cure of meats, fish, vegetables, pickles etc.

(b) Concentrated Sugar Solutions (Sugar Syrup) may be

employed, extensively in the preser-vation of lime juice, fruits etc.

(i) Radiation

Radiation refers to — ‘any form of radiant energy emission or divergence, as of energy in

all directions from luminous bodies, radiographical tubes, particle

accelerators, radioactive ele-ments, and fluorescent substances’.

It has

been established beyond any reasonable doubt that radiation exerts its various effects on the cells, depending upon

its wavelength, intensity, and duration as well. Generally, one may come across

two kinds of radiation which would cause a bactericidal

effects on microbes, or usually referred to as the ‘sterilizing radiation’, namely :

(a) Ionizing

Radiation, and

(b) Nonionizing

Radiation.

Each of

the aforesaid types of radiation shall be treated individually in the sections

that follows :

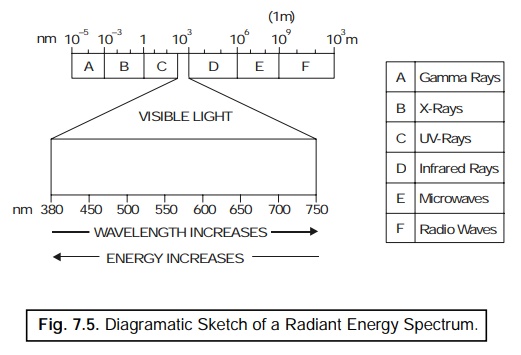

Ionizing Radiation

The ionizing radiation normally possess a

wavelength distinctly shorter in comparison to the nonionizing radiation (size

< 1 nm) e.g., γ-rays, X-rays, or high-energy electron beams.

Figure

7.5 vividly depicts that the said ionization

radiation invariably carries a significant quan-tum of energy ranging

between 10–5 nm (γ-rays) to 10–3 nm (X-rays).

γ-Rays : These are emitted by radioactive

cobalt (Co),

X-Rays : These are produced by X-ray

machines, and

Electron Beams : These are generated by

accelerating electrons to high energies in special machines.

Visible light plus other forms of radiant energy

invariably radiate via space as waves

of various lengths.

Ionizing radiation viz., γ-rays and

X-rays possess a wavelength shorter than 1 nm.

Nonionizing radiation viz., UV-light has a wavelength ranging between 1–380 nm, where the

visible spectrum commences.

Salient Features. The

various salient features of the Ionizing Radiation are as stated under

:

(1) The γ-rays usually penetrate deeply but would essentially

require reasonably longer dura-tion, extended to several hours, for the

sterilization of relatively large

masses.

(2) High-energy electron beams do

possess appreciably lower penetrating power ; however, need only a few seconds of exposure to cause sterilization.

(3) Major

causative effect of ionizing radiation

being its distinct ability to the ionization of water, which in turn gives rise

to highly reactive hydroxyl radicals [OH•]*.

Interestingly, these radi-cals critically interact with the cellular organic

components, especially the DNA, and thereby kill the cell ultimately.

(4) High-energy electron beams (ionizing radiation)

has

recently gained an enormous world-wide acceptance, recognition, and utilities

for the exclusive sterilization of such substances as : pharmaceuticals, disposable dental materials, and disposable medical supplies. A few

typical examples are : plastic syringes, catheters, surgical

gloves, suturing materials.

Note. Radiation has virtually replaced ‘gases’ for

the ultimate sterilization of these items.

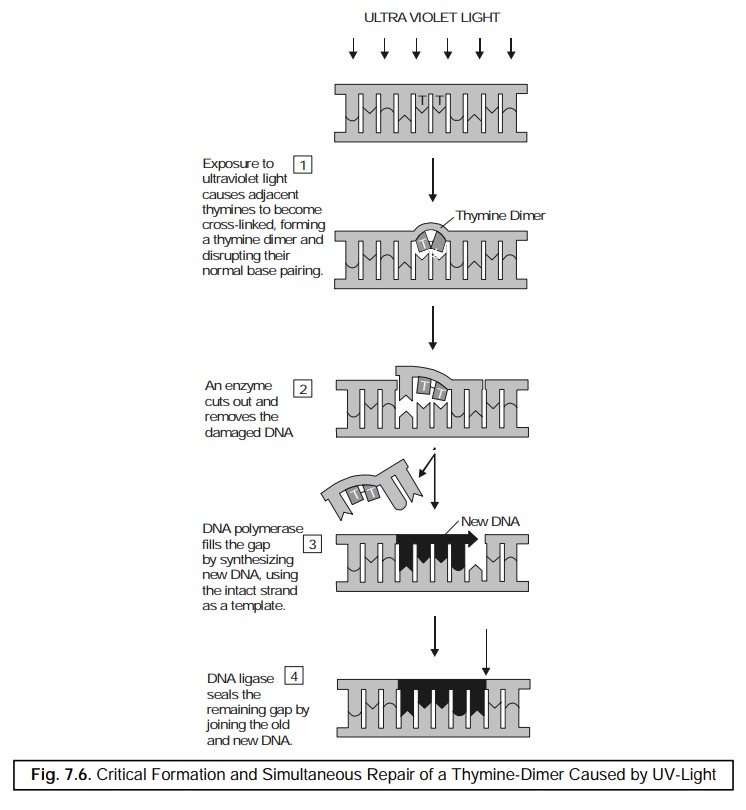

Nonionizing Radiation

Predominantly

the nonionizing radiation possesses

a distinct wavelength much longer than that of the corresponding ionizing radiation, invariably greater

than about 1 nm.

Example : UV-light : The most

befitting example of the nonionizing

radiation is the UV-light, which

is able to cause permanent damage to

the DNA of exposed cells by virtue

of creation of newer additional bonds between the ‘adjacent thymines’ strategically present in the DNA-chains, as illus-trated in Figure :

7.6. The said figure evidently shows the formation of a thymine dimer after being exposed duly to the UV-light whereby the adjacent

thymines may be rendered into a cross-linked

entity. Importantly, in the absence

of the visible light, this

particular mechanism is usually employed by

a cell to afford the repair of the prevailing damage caused.

In

reality, these ‘thymine dimers’ are

found to cause effective inhibition in correcting replica-tion of the DNA in

the course of division (reproduction) of the cell. It has been duly established

that the UV-wavelengths at nearly 260 nm

are most effective and useful for

killing microbes due to the fact that

these are exhaustively absorbed by the cellular DNA.

Advantages of UV Light : are as

given under :

(a) It

controls and maintains the miroorganisms in the air.

(2) A ‘UV-Radiation Lamp’ or a ‘Germicidal Lamp’ is abundantly and

profusely employed in a variety of such sensitive areas as : operation theaters, hospital rooms,

nurseries, and cafeterias.

(3) UV Light or Radiation is

invariably employed to sterilize a plethora of highly sensitive biological products commonly used in

the therapeutic armamentarium, such

as : serum, toxins, and a variety of vaccines.

(4) UV Light is also employed to sterilize the

drinking water in homes, hospitals, and public places.

(5) UV Radiation is also used for the

sterilization of the ultimate treated

‘municipal-waste waters’ for agriculture and horticulture purposes.

Disadvantages of UV Light : These are

as stated under :

(1) UV Radiation is found to be not very

penetrating in nature ; and, therefore, the microorgan-isms intended to be

killed should be exposed almost directly to the UV-rays.

(2) Besides,

such microbes that are adequately shielded (protected) by means of textiles, col-oured, glass, and paper (i.e., textured cellulose

materials) are observed to be least affected by the UV radiation.

(3) Serious Problem. In fact, UV light poses a serious problem in

causing permanent damage to human

eyes on direct exposure, besides, prolonged exposure may even cause sun burns as well as skin cancers.

Note : (1) Antimicrobial effect of UV sunlight is

on account of the exclusive formation of the ‘singlet oxygen in the cytoplasm’.

(2) Microwaves (in the microwave oven) do not

exhibit any direct effect on the microbes, but kill them indirectly by heating

the food stuff.

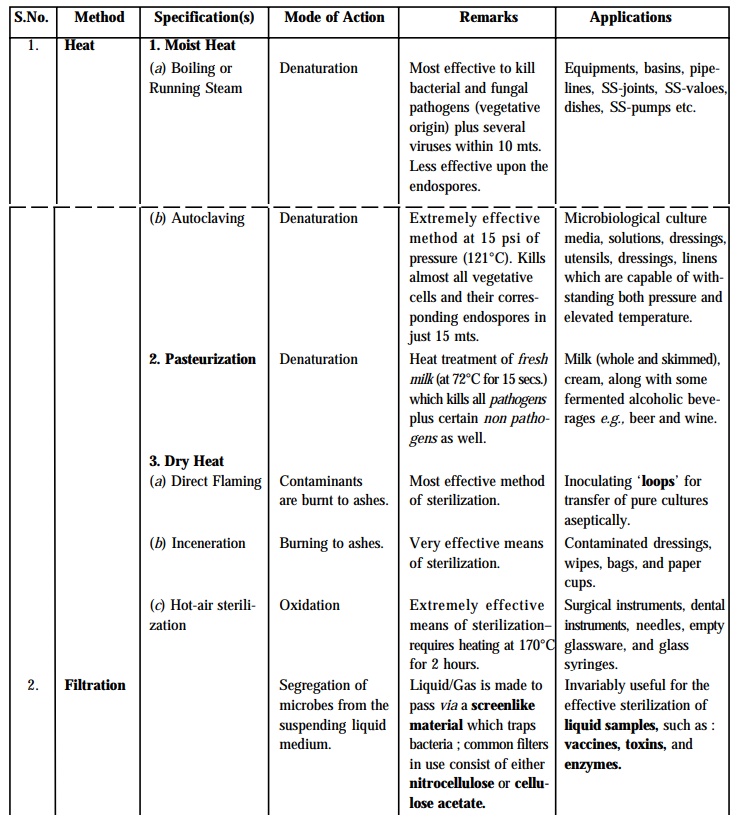

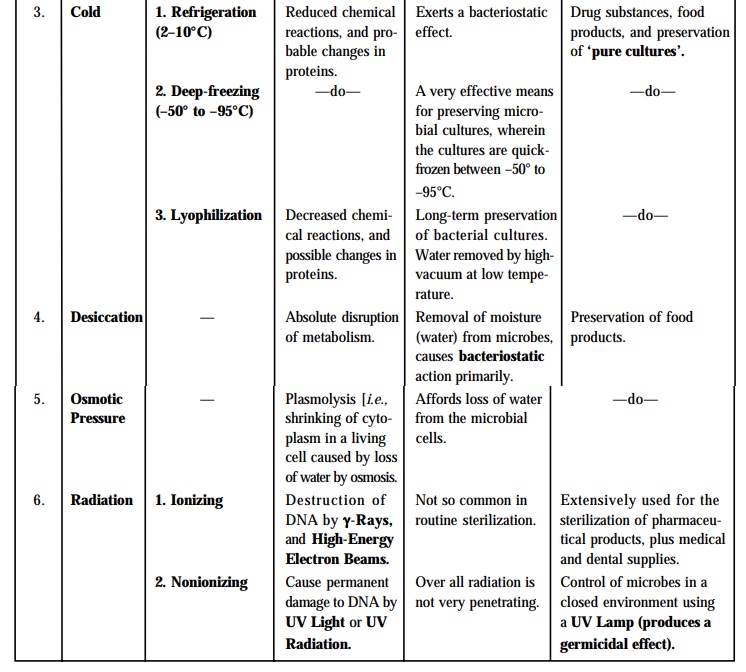

A

comprehensive summary of the various physical methods invariably utilized for

the effective control of the microbial growth has been duly recorded in Table :

7.3.

Table : 7.3. Comprehensive Summary of Various

Physical Methods Utilized for the Effective Control of Microbial Growth

Related Topics