The Theory of Drying

| Home | | Pharmaceutical Technology |Chapter: Pharmaceutical Engineering: Drying

Theories of drying are limited in application in that drying times are normally experimentally determined.

THE THEORY OF DRYING

Theories

of drying are limited in application in that drying times are normally

experimentally determined. Nevertheless, an appreciation of the scope and

limitations of the different drying methods is given. The following terms are

employed in discussing drying: humidity and humidity of saturated air, relative

humidity, wet bulb temperature, and adiabatic cooling line. Other terms may be

defined as follows:

Moisture

content: This is usually expressed as a weight per unit weight of dry solids.

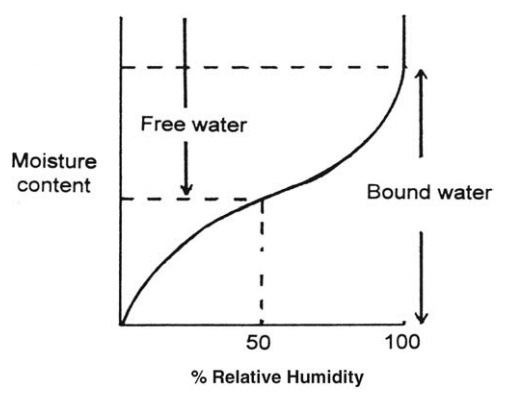

Equilibrium moisture content: If a material is exposed to air at a given

temperature and humidity, it will gain or lose moisture until equilibrium is

reached. The moisture present at this point is defined as the equilibrium

moisture content for the given exposure conditions. At a given temperature, it

will vary with the partial pressure of the water vapor in the surrounding

atmosphere. This is shown for a hypothetical hygroscopic material in Figure 7.1

in which the equilibrium moisture content is plotted against the relative humidity.

Any moisture present in excess of the equilibrium moisture content is called

“free water.”

FIGURE 7.1 The relation between equilibrium

moisture content and relative humidity for a hygroscopic solid.

Equilibrium

moisture content curves vary greatly with the type of material examined.

Insoluble, nonporous materials, such as talc or zinc oxide, give equilibrium

moisture contents of almost zero over a wide humidity range. A moisture content

of between 10% and 15% may be expected for cotton fabrics under normal

atmospheric conditions. Drying below the equilibrium moisture content for room

conditions may be deliberately undertaken, particularly if the material is

unstable in the presence of moisture. Subsequent storage conditions then become

important for product stability.

The

equilibrium moisture content at 100% relative humidity represents the minimum

amount of water associated with the solid that still exerts a vapor pressure

equal to a separate water surface. If the humidity is reduced, only part of the

water evaporates before a new equilibrium is established. The water retained at

less than 100% relative humidity must, therefore, exert a vapor pressure below

that of a dissociated water surface. Such water is called “bound water.” Unlike

the equilibrium moisture content, bound water is a function of the solid only

and not of the surroundings. Such water is usually held in small pores bound

with highly curved menisci, is present as a solution, or is adsorbed on the

surface of the solid.

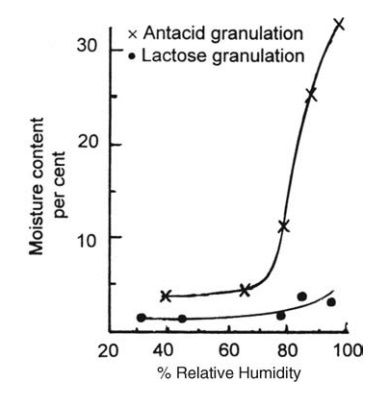

The

value of equilibrium moisture content curves is illustrated by the examples

given in Figure 7.2. The equilibrium moisture content of the antacid granules,

composed of magnesium trisilicate granulated with syrup, is a sen-sitive

function of relative humidity. If it is to be dried to a moisture content

FIGURE 7.2 Equilibrium moisture content

curves for two tablet granulations.

With knowledge of the humidity

of the circulating air, psychrometric charts may be used to determine the

minimum air temperature that will dry the material to the required standard.

(In fact, the temperature has an effect on the equilibrium moisture content

that is independent of the humidity, but this can be neglected to a first

approximation.)

The lactose

granulation, on the other hand, has a low sensitivity to relative humidity.

Drying at low relative humidities derived from high air temperatures causes

only a marginal decrease in the final moisture content, and the stability of

the active ingredients associated with the lactose filler could be impaired.

This argument may only be applied to the final moisture content. It is not

related to the rate of drying that would, of course, be greater at higher

temperatures and lower humidities.

The effects of

storage after drying may also be assessed from the equi-librium moisture

content curves. Storage conditions are not critical for the lac-tose

granulation. If the antacid formulation was stored at a relative humidity of

only 65%, it would, given sufficient time, absorb moisture until the content

was 9%. This could be associated with poor flow characteristics and its

attendant difficulties during compression.

Dynamic vapor

sorption techniques now exist, which allow thorough studies of moisture

association with solids under a wide range of relative humidity conditions

based on microbalance technology.

Related Topics