The Measure of Pressure Intensity

| Home | | Pharmaceutical Technology |Chapter: Pharmaceutical Engineering: Fluid Flow

The density term should be the difference between the density of the liquid in the column and the density of the surrounding air.

THE MEASURE OF PRESSURE

INTENSITY

Application

of equation (2.3) to the column of liquid shown in Figure 2.3A gives

PA

- P1 = -ρgh

and

P1

= PA + ρgh (2:4)

The

density term should be the difference between the density of the liquid in the

column and the density of the surrounding air. The latter is relatively small,

and this discrepancy can be ignored. P1 is the absolute pressure at

the point indicated, and PA is the atmospheric pressure. It is often

convenient to refer to the pressure measured relative to atmospheric pressure,

that is, P1 - PA. This is called the gauge pressure and

is equal to ρgh. SI unit for pressure is N/m2. Alternatively, the

gauge pressure can be expressed as the height or head of a static liquid that

would produce pressure.

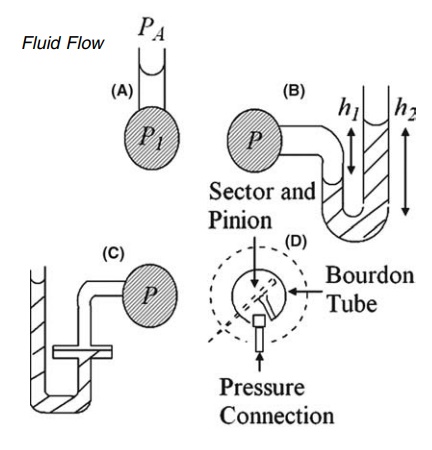

Figure

2.3A represents the simplest form of a manometer, a device widely used for the

measurement of pressure. It consists of a vertical tube tapped into the

container of the fluid being studied. In this form, it is confined to the

FIGURE 2.3 Pressure measurement apparatus

(A) vertical; (B) U-tube; (C) modified U-tube manometers and (D) Bourdon gauge.

pressure

measurement of liquids. This device is unsuitable for the measurement of very

large heads, because of unwieldy construction, or very small heads, because of

low accuracy. The U-tube manometer, shown in Figure 2.3B, may be used for the

measurement of higher pressures with both liquids and gases. The density of the

immiscible liquid in the U-tube, ρ1, is greater than the density of

the fluid in the container, ρ2. The gauge pressure is given by

P

= h1ρ1g

- h2ρ2g

The disadvantage of

reading two levels may be overcome by the modification in Figure 2.3C. The

cross-sectional area of one limb is many times larger than that of the other,

and the vertical movement of the heavier liquid in the wider arm can be

neglected and its level is assumed to be constant.

Sloping the reading

arm of the manometer can increase the accuracy of the pressure determination

for small heads with any of the manometers just described. The head is now

derived from the distance moved along the tube and the angle of the slope.

The Bourdon gauge, a

compact instrument widely used for the measure-ment of pressure, differs in

principle from the manometer. The fluid is admitted to a sealed tube of oval

cross section, the shape of which is shown in Figure 2.3D. The straightening of

the tube under internal pressure is opposed by its elasticity. The movement to

an equilibrium position actuates a recording mechanism. The gauge is calibrated

by an absolute method of pressure measurement.

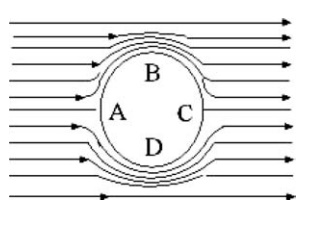

The

principles of pressure measurement also apply to fluids in motion. However, the

presence of the meter should minimize perturbation in flow. A calming section,

in which a flow regime becomes stable, is present upstream from the pressure

tapping, and the edge of the latter should be flush with the inside of the

container to prevent flow disturbance.

FIGURE 2.4 Flow of a fluid past a cylinder.

Related Topics