The Filtration of Air

| Home | | Pharmaceutical Technology |Chapter: Pharmaceutical Engineering: Filtration

Removal of particulate matter from air together with control of humidity, temperature, and distribution comprise air conditioning.

THE FILTRATION OF AIR

Removal

of particulate matter from air together with control of humidity, temperature,

and distribution comprise air conditioning. Solid and liquid par-ticles are

most commonly arrested by filtration, although other methods, such as electrostatic

precipitation, cyclones, and scrubbers, are used in some circum-stances. The

objective may be simply the provision of comfortable and healthy conditions for

work or may be dictated by the operations proceeding in the area. Some

industrial processes demand large volumes of clean air.

In

this section, we shall be concerned mainly with air filtration, the objective

of which is the reduction in number or complete removal of bacteria. This is

applied, with varying stringency, to several operations associated with

pharmacy. Where sterilization is the objective and the presence of inanimate

particles is of secondary importance, other methods, such as ultraviolet

radia-tion and heating, must be added.

Bacteria

rarely exist singly in the atmosphere but are usually associated with much

larger particles. For example, it has been shown that 78% of particles carrying

Clostridium welchii were greater than 4.2 x 10-6 m. The average

diameter exceeded 10 x 10-6 m. On this basis, it has been suggested

that air filters that are 99.9% efficient at 5 x10-6 m are adequate

for filtration of air supplied to operating theaters and dressing wards

(Williams et al., 1961). On the other hand, filters used to clean air supplied

to large-scale aerobic fermentation cultures must offer a very low probability

that any organism will penetrate during the process. This became important in

the deep-culture production of penicillin when the ingress of a single

penicillinase-producing organism could be disastrous. Similarly, stringent

conditions are laid down for the supply of air to areas where sterile products

are prepared and handled.

The Mechanism of Air Filtration

A

theoretical foundation for the filtration of air by passage through fibrous

media was laid in the early 1930s by studies of the flow of suspended particles

around various obstacles. In studies of the filtration of smokes (Suits, 1961;

Hinds, 1999), it has been shown that a number of factors operate simultaneously

in the arrest of a particle during its passage through a filter, although their

relative importance varies with the type of filter and the conditions under

which it is operated. These factors may be listed as follows:

·

Diffusion effects due to Brownian movement

·

Electrostatic attraction between particles and fibers

·

Direct interception of a particle by a fiber

·

Interception as a result of inertial effects acting on a

particle and causing it to collide

with a fiber

·

Settling and gravitational effects

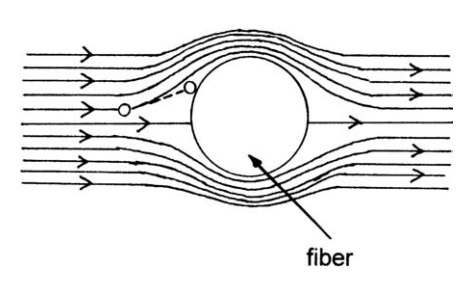

FIGURE 11.6 Inertial capture of a particle

by a fiber.

Air

filters operate under conditions of streamline flow, as indicated by the

streamlines drawn around a cylindrical fiber shown in cross section in Figure

11.6. It was assumed that capture of a particle takes place if any contact is

made during its movement around the fiber. Once capture occurs, the particle is

not re-entrained in the airstream and is deposited deeper in the bed. Support

for this assumption has been found by using an atomized suspension of

Staphylococcus albus and spores of Bacillus subtilis (Terjesen and Cherryl,

1947). Nevertheless, some fiber filters are treated with viscous oils,

presumably to make capture more positive and to reduce re-entrainment.

If

a particle remains in a streamline during passage around the fiber, capture

will occur only if the radius of the particle exceeds the distance between

streamline and fiber, a dimension dependent on the diameters of the particle

and the fiber. This mechanism, termed “capture by direct interception,” is

independent of the air velocity except in so far as the streamlines are

modified by changes in air velocity.

Deviation

of particles from streamlines can occur in a number of ways (Hinds, 1999;

Reist, 1993). The chance of capture will increase if Brownian movement causes

appreciable migration across streamlines, an effect only important for small

particles (<5 x 10-7

m) and low air speeds, when the time spent in the vicinity of a fiber is

relatively large. These conditions also apply to capture, which is the result

of electrostatic attraction.

The

inertial mechanism depends on the mass of the particle, the fiber diameter, and

the velocity of approach. The particle deviates from the streamline and follows

the broken line shown in Figure 11.6. Capture occurs if the devia-tion, which

increases as the mass and velocity of the particle increase, brings the

particle into contact with the fiber.

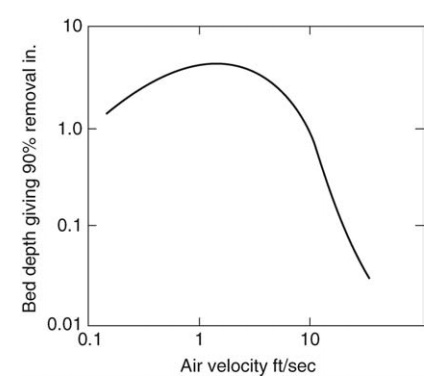

The

simultaneous operation of mechanisms, at least one of which demands low air

speeds and fine particles for effectiveness and another which requires large

particles traveling at high speeds, suggests that maximum penetration could

occur at an intermediate air speed. Conversely, there is, for any given

conditions, an optimal particle size for which the combined filtration effects

are a minimum and penetration is a maximum. The former was confirmed with a

variety of inanimate aerosols. A diagrammatic representation of the interaction

of mecha-nisms was also given, and this is reproduced in Figure 11.7.

Similar

effects were demonstrated for bacterial aerosols (Humphrey and Gaden, 1956).

Estimated the efficiency with which a glass fiber mat collected

FIGURE 11.7 Interaction of the mechanisms

of particle arrest.

FIGURE 11.8 Effect of airstream velocity on the removal of bacterial spores by a filter.

The Design, Operation, and Testing of Air Filters

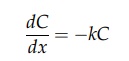

Granular

beds, fibrous media, and “absolute filters” prepared from cellulose and

asbestos are used for high-efficiency air filtration. With fibrous and granular

filters, the fractional reduction in particle content is assumed to be the same

through successive incremental thicknesses of the filter. We may, therefore,

rewrite equation (2).

where

C represents the number of particles entering a section of thickness dx. The constant, k, is a measure of the filter’s ability to retain a particle and is

a complex function of fiber diameter, interfiber distance, and operational air

velocity. Integration between inlet and outlet conditions gives

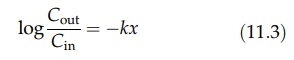

The

use of this log penetration effect in filter design has been described

else-where (Gaden and Humphrey, 1955). If a certain filter thickness is capable

of retaining 90% of the entering particles, then if 106 particles

enter, 105 will pen-etrate. If six thicknesses are used, then the

relation above predicts that only one particle will penetrate. The log

penetration effect has been confirmed for fibrous filters and for granular beds

(Humphrey and Gaden, 1956; Cherry et al., 1951), respectively. It must be

stressed, however, that both fibrous and granular filters present passages very

much greater than the fine particles they remove. Abso-lute sterility or

absolute filtration at a certain particle size cannot be achieved. However, design

variables, such as the fiber diameter, the density with which fibers are

packed, the thickness of the filter, and the air speed. For example, these

variables may be varied to give air that, for a given input contamination, is,

with a high statistical probability, sterile.

In

an early study, Terjesen and Cherryl used a bacterial aerosol and a Bourdillon

slit sampler to test the suitability of filters for air sterilization (Terjesen

and Cherryl, 1947). They showed that 0.075-m slabs of slag wool composed of

fibers, most of which were less than 6 x 10-6 m and compressed to a

suitable density, gave sterile air when operated for fifteen days at a face

velocity of 0.152 m/sec. A similar efficiency was found for filters composed of

glass fibers of similar diameters (Cherry et al., 1951). Resin-bonded filter

mats composed of glass fibers, 12 x 10-6 to 13 x 10-6 m

in diameter, have also been described. A number of these mats assembled to give

a filter 0.304 m deep were effective in the removal of bacteria.

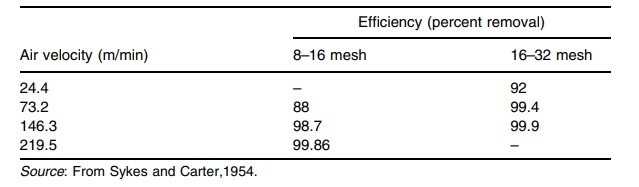

Bacteria

may be effectively removed by passing air through deep granular beds of

activated carbon, alumina, and other materials. Table 11.1 gives data on the

efficiency of alumina in a bed 0.381 m deep for the removal of Serratia

marcescens from air (Sykes and Carter, 1954). The effect of two design

variables, granule size and air speed, is illustrated.

The

extremely hazardous nature of radioactive dusts has promoted the design of

high-efficiency air filters for use in establishments where such mate-rials are

handled. These filters may be used for any application requiring extremely pure

air. The evolution of filters that remove 99.995% of particles in the range 1 x

10-7 to 5 x 10-7 m has been described by White and Smith

(White and Smith, 1960). A medium in paper form was constructed from cellulose

and asbestos. This could be pleated round corrugated spacers to give a large

filtering area in a relatively small space. A paper composed of very fine glass

fibers was

TABLE 1 Removal of Serratia marcescens

with a 0.3-m Bed of Alumina Granules

The

general object of design in all filters is the virtual certainty of removing

the particles under consideration with a medium offering minimal resistance to

the flow of air. Unlike liquid clarifiers, air filters become more efficient

with time because accumulation of particles restricts the passages through the

medium. This deposition causes an increase in the pressure differential

required to maintain a given flow rate. When the filter has become laden with a

certain amount of dust, it must be cleaned or replaced. The life of

high-efficiency air filters may be lengthened by passing the air first through

a coarse or “roughing” filter, which removes the larger particles.

The

use of bacterial aerosols as tracer organisms to test the efficiency of filters

has already been described. Other tests with inanimate dusts are more generally

used for the evaluation of filter performance. For general ventilation

purposes, two tests are specified. The first determines gravimetrically the

capacity of the filter to hold dust and still function satisfactorily. A

standard dust of 5 x 10-6 or 26 x 10-5 m is passed into

the filter until a specified increase in air flow resistance occurs. The second

test, which is also applicable to high-efficiency filters, determines the

fraction of a methylene blue aerosol that passes through the filter under given

conditions. The aerosol is generated by atomizing a 1% aqueous solution of

methylene blue. The droplets dry to give a cloud of particles, 90% of which are

below 2 x 10-7 m. The test is, therefore, extremely stringent. The

cloud is passed through the filter at a constant rate (10-3 m3/min)

and then through a strip of porous paper, which collects any methylene blue

particles that have penetrated. The stain due to the dye, after intensification

in steam, is compared with a series of similar stains that correspond to known volumes

of unfiltered air. Thus, if 60 x 10-3 m3 of filtered air

gives a stain that matches that produced by 1.2 x 10-5 m3

of unfiltered air, the penetration is 0.02% (Green and Lane, 1957). Both tests

are fully described in BS 2831:1957. An alternative method of evaluating

penetration employs a cloud produced by the atomization of a solution of sodium

chloride. After passage through the filter, part of the air is passed through a

hydrogen flame. The intensity of the sodium flame produced is estimated with a

photoelectric cell.

Related Topics