Sterilization Considerations

| Home | | Pharmaceutical Microbiology | | Pharmaceutical Microbiology |Chapter: Pharmaceutical Microbiology : Sterile Pharmaceutical Products

It is axiomatic that whatever method is chosen, the process should not cause damage to the product. By reference mostly to moist heat sterilization processes (the reader should remember that there are parallel approaches to other methods of sterilization) this section illustrates the factors that must be considered in the design of a sterilization process.

STERILIZATION CONSIDERATIONS

It is axiomatic that whatever method

is chosen, the process

should not cause

damage to the product. By reference mostly to moist

heat sterilization processes (the reader should

remember that there are

parallel approaches to other methods

of sterilization) this section illustrates the factors

that must be considered in the design of a sterilization process.

The simplest

method of sterilization, for an aqueous product, is to expose

it to the standard moist

heat sterilization conditions, i.e. holding the product at 121 °C for

15 minutes, a process termed

overkill. These conditions are quite severe and therefore

milder conditions might be

considered, i.e. a lower holding

temperature than 121 °C,

or a shorter holding

period than 15 minutes for a product prone to degradation. The minimum holding

period for moist heat sterilization might be considered to be 8 minutes at 121 °C. However, in reality a slightly shorter holding period may be satisfactory if the lethality of the whole

autoclave cycle (including heat-up and cooling phases) is calculated using F0 values and shown to afford the requisite SAL. F0 values of 8 minutes

or more

are normally considered satisfactory. Use of

lower temperatures and times gives an autoclave

process partly based on the initial bioburden and partly on the

known stability of the product.

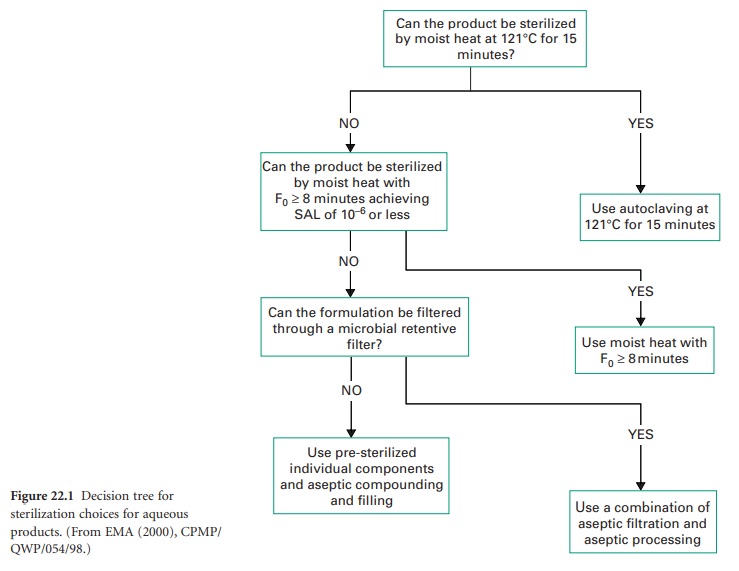

A) Decision Trees

Where it is not possible to sterilize a product in its final container by terminal heat

sterilization at 121

°C for 15 minutes, decisions have to be made

to use an alternative

method. The options include filtration in combination with aseptic

processing, but readers

should note that aseptic processing by itself is not a method

of sterilization, rather

of preventing contamination of the product whilst it is manufactured from

individually sterilized components.

The European Agency for the Evaluation of Medicinal

Products in 2000 produced an Annex for Guidance on Development Pharmaceuticals (CPMP/QWP/155/96) showing decision trees for the selection of sterilization

methods. The tree for the sterilization choices for aqueous products is shown

in Figure 22.1.

The initial premise

is that if the products

may be sterilized at 121 °C for 15

minutes, that process should

be used. The next alternative is that if the product

is stable when

an F0 of 8 minutes or more can be used,

then the reduced

moist heat process should be undertaken. If heat processes are unsuitable (an F0 < 8 minutes

will not achieve

the necessary SAL),

then filtration through

a microbial filter

should be chosen as the process to render the product sterile.

If that process cannot be utilized, then presterilizing of stable components and aseptic compounding and filling must

be considered. The described methods generally show

decreasing levels of sterility assurance on moving down

the tree. It is therefore imperative to remember that the highest

level of sterility assurance

is achieved in conjunction with the

lowest presterilization bioburden. The use of inappropriate heat-labile packaging material cannot by itself be the reason for the use of aseptic processing, and any manufacturer should use the best sterilization method achievable for a given

formulation before selecting the packaging

material. The manufacture of biotechnology products, which are typically

heat-labile peptides, proteins

or nucleic acids, will provide a

challenge as their overall stability dictates their

positioning near the bottom of the

decision tree. They may require

sterilization by submicron (< 0.1 μm) filtration and filling and finishing using aseptic processes. The overall

SAL for terminally sterilized products

should be less than 10−6 and for aseptically

produced products less than 10−3.

B) Problems Of Drug Stability

Certain issues

of product instability may be resolved by formulation or careful selection

of vehicle. Aminophylline injection, for example, is a solution of the drug

in Water for Injections Injections

free from

carbon dioxide, as the presence ![]()

![]() of this gas causes precipitation of the active

ingredient. Similarly, promethazine injection is a solution

of the active ingredient in Water for free

from dissolved air, as the presence of oxygen would cause promethazine

oxidation. Removal of these gases

can be accomplished by prior boiling;

additionally, the product may be packed under

an atmosphere of nitrogen to eliminate oxygen from

the headspace in the ampoule.

of this gas causes precipitation of the active

ingredient. Similarly, promethazine injection is a solution

of the active ingredient in Water for free

from dissolved air, as the presence of oxygen would cause promethazine

oxidation. Removal of these gases

can be accomplished by prior boiling;

additionally, the product may be packed under

an atmosphere of nitrogen to eliminate oxygen from

the headspace in the ampoule.

Formulations may be further

stabilized by the

inclusion of

inactive ingredients with specific functions.

Although the British Pharmacopoeia (2010) describes

chloramphenicol eye drops

as a sterile solution of chloramphenicol in purified water, normally

the system is buffered for stability with a boric

acid/sodium borate buffer (see Table 22.1). Sodium

metabisulphite may be found in many products as an

antioxidant to prevent degradation of the active, examples being

promethazine injection and

adrenaline injection. The presence of antimicrobial preservatives may be found

in multiple-dose products, to

prevent microbial growth following contamination during use. Many

of these formulation considerations relate to stability of the product

during storage, but an understanding of thermostability is required for the selection of the appropriate sterilization process.

The choice of sterilization method

depends on the thermostability of the active ingredient. Moist heat sterilization can only

be applied to drugs that

are heat-stable in aqueous

solution and are not subject

to hydrolysis. Where aqueous solutions are so unstable

that chemical stabilization

is impossible, consideration should be given to sterilization of the drug itself by dry heat processes

(160 °C for 2 hours or its equivalent at higher temperatures) in its final

container and dissolution immediately before use by the addition

of sterile Water for Injections

BP.

For drugs which

are both thermolabile and unstable in aqueous

solution, a sterile

solution of the drug may

be freeze-dried in its final container

and is again reconstituted as above just

before use. Examples

include many antibiotics

and Hyaluronidase Injection BP.

Related Topics