Parenteral Controlled Release Systems

| Home | | Biopharmaceutics and Pharmacokinetics |Chapter: Biopharmaceutics and Pharmacokinetics : Controlled Release Medication

One of the major advantages of parenteral controlled drug delivery systems is that the duration of action can be extended for days or months and sometimes upto a year.

PARENTERAL CONTROLLED RELEASE SYSTEMS

One of the major advantages of parenteral controlled drug delivery systems is that

the duration of action can be extended for days or months and sometimes upto a

year. The prime drawback is that,

once administered, the drug cannot be easily removed if an undesirable action

is precipitated or if the drug is no longer needed. Most of such systems are

administered by subcutaneous and intramuscular routes and few by intravenous

and intraperitoneal routes. Subcutaneous route is limited to well absorbed

water-soluble drugs like insulin and dose volume is limited to 0.5 to 1.5 ml.

Deep intramuscular route is suitable for polymeric systems or slightly soluble

drugs, the volume size restricted to 2 ml. Intravenous route is useful for

administration of liposomes, nanoparticles, erythrocytes and polypeptides. An

important criteria for this route is drug particle size. A disadvantage of i.v.

route is that the system may be taken up by the reticuloendothelial system but

the same can be put to use in targeting drugs to such a system. Intraperitoneal

route is important in targeting of antineoplastics into the lymphatic system.

The vehicle, polymers and other substances used in

the formulation of parenteral controlled-release dosage forms should be

sterile, pyrogen free, nonirritating, biocompatible and biodegradable into

nontoxic compounds within an appropriate time, preferably close to the duration

of drug action.

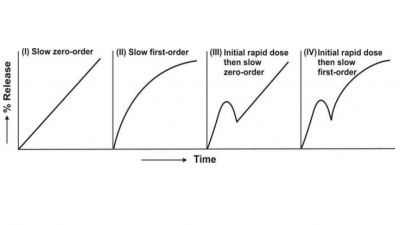

There are several approaches to achieve controlled

drug delivery via parenteral route, the release being controlled by

dissolution, diffusion, dissociation, partitioning or bioerosion. The systems

can be broadly classified as:

A. Injectables:

1. Solutions

2. Dispersions

3. Microspheres and Microcapsules

4. Nanoparticles and Niosomes

5. Liposomes

6. Resealed Erythrocytes

B. Implants

C. Infusion Devices:

1. Osmotic Pumps

2. Vapor Pressure Powered Pumps

3. Battery Powered Pumps

A. Injectables

1. Solutions

Both aqueous as well as oil solutions may be used

for controlled drug release. With aqueous

solutions (given intramuscularly), the drug release may be controlled in

three ways:

i. By increasing the viscosity of

vehicle by use of MC, CMC or PVP and thus, decreasing molecular diffusion and

localizing the injected drug.

ii. By forming a complex with macromolecules like

MC, CMC or PVP from which the drug dissociates at a controlled rate (only free

drug will get absorbed).

iii. By forming complexes that

control drug release not by dissociation but by reducing the solubility of

parent drug e.g. protamine zinc insulin and cyanocobalamin zinc tannate.

Oil solutions control the release by

partitioning the drug out of the oil in the

surrounding aqueous biofluids. Vegetable oils like arachis oil, cottonseed

oil, etc. are used for such a purpose. The method is applicable only to those

drugs which are oil soluble and have optimum partition coefficient.

2. Dispersions

Dispersed systems like emulsions and suspensions can

be administered by i.m., s.c. or i.v. routes. Among emulsions, the o/w systems have not been used successfully since

absorption of drug incorporated in the oil phase is rapid due to large

interfacial area and rapid partitioning. Similarly, few w/o emulsions of

water-soluble drugs have been tried for controlled-release. Multiple emulsions of w/o/w and o/w/o

types (more correctly, double emulsions)

are becoming popular since an additional reservoir is presented to the drug for partitioning which can effectively

retard its release rate (Fig. 14.13).

Control of drug release from suspensions is easier and predictable. Drug dissolution and

subsequent diffusion are the main rate controlling steps. Release of

water-soluble drugs can be retarded by presenting it as oil suspension and vice versa for oil soluble drugs.

Factors to be considered in the formulation of such a system include -

i. Solid content : should be

ideally in the range 0.5 to 5.0%

ii. Particle size : this factor is very important

since larger the particle size, slower the dissolution; however, larger

particles have their own disadvantages like causing irritation at the injection

site (size should therefore be below 10 microns), poor syringeability and

injectability and rapid sedimentation. The latter problem can be overcome by

use of viscosity builders which also retard drug diffusion.

Fig. 14.13 Multiple emulsions for parenteral controlled-release systems

Aqueous suspensions can be given by i.m. or s.c.

routes. Generally crystalline and stable

polymorphic forms of the drug are chosen rather than amorphous forms to delay

release. Solubility can be further reduced by salt or complex formation e.g.

crystalline zinc insulin shows more prolonged action than amorphous zinc insulin

complex. Oil suspensions, generally given i.m., prolong drug action much more in

comparison to oil solution and

aqueous suspension since drug release involves two rate- limiting steps viz.

dissolution of drug particles, and partitioning of the dissolved drug from oil

to the aqueous biofluids.

3. Microspheres and Microcapsules

Microspheres are free flowing powders

consisting of spherical particles of size ideally less than 125 microns that can be suspended in a suitable aqueous

vehicle and injected by an 18 or 20 number needle. Each particle is basically a

matrix of drug dispersed in a polymer from which release occurs by a

first-order process. The polymers used are biocompatible and biodegradable e.g.

polylactic acid, polylactide coglycolide, etc. Drug release is controlled by

dissolution/degradation of matrix. Small matrices release drug at a faster rate

and thus, by using particles of different sizes, various degrees of

controlled-release can be achieved. The system is ideally suited for controlled-release

of peptide/protein drugs such as LHRH which have short half-lives and otherwise

need to be injected once or more, daily, as conventional parenteral

formulations. In comparison to peptides, proteins are difficult to formulate

because of their higher molecular weight, lower solubility and the need to

preserve their conformational structure during manufacture.

In order to overcome uptake of intravenously

administered microspheres by the reticuloendothelial system and promote drug

targeting to tumors with good perfusion, magnetic

microspheres were developed. They are prepared from albumin and magnetite (Fe2O3)

and have a size of 1.0 micron to permit intravascular injection. The system is

infused into an artery that perfuses the target site and a magnet is placed

over the area to localize it in that region. A 100 times higher concentration

of doxorubicin was attained at the target site by such an approach with just

half the i.v. dose.

Microcapsules differ from microspheres in that

the drug is centrally located within the

polymeric shell of finite thickness and release may be controlled by

dissolution, diffusion or both. Quality microcapsules with thick walls

generally release their medicaments at a zero-order rate. Steroids, peptides

and antineoplastics have been successfully administered parenterally by use of

controlled-release microcapsules.

4. Nanoparticles and Niosomes

Nanoparticles are also called as nanospheres or nanocapsules depending upon whether the drug is in a polymer matrix or encapsulated in a shell. They

differ from microspheres in having submicron particles in the nanometer size

range—10 to 1000 nm. The polymers used are the usual biodegradable ones. The

main advantage of this system is that it can be stored for upto 1 year and can

be used for selective targeting via reticuloendothelial system to liver and to

cells that are active phagocytically.

Like nanoparticles, niosomes are inexpensive alternatives to liposomes. They are closed

vesicles formed in aqueous media from nonionic surfactants with or without the

presence of cholesterol or other lipids.

5. Liposomes

The term liposomes

(meaning lipid body) was derived on

the basis of names of subcellular particles like lysosome and ribosome. It is

defined as a spherule/vesicle of lipid bilayers enclosing an aqueous

compartment. The lipid most commonly used is phospholipid. Sphingolipids,

glycolipids and sterols have also been used to prepare liposomes. Their size

ranges from 25 to 5000 nm. Depending upon their structure, liposomes are

classified as:

i. MLV (multilamellar

vesicles) : These liposomes are made of series of concentric bilayers of

lipids enclosing a small internal volume.

ii. OLV (oligolamellar vesicles) : These are made of 2 to 10 bilayers of

lipids surrounding a large internal volume.

iii. ULV (unilamellar vesicles) : These are made of single bilayer of lipids.

They may be SUV (small unilamellar

vesicles) of size 20 to 40 nm, MUV (medium

unilamellar vesicles) of size 40 to

80 nm, LUV (large unilamellar vesicles)

of size 100 to 1000 nm or GUV (giant unilamellar vesicles) of size

greater than 1000 nm.

A large variety of drugs (antineoplastics,

antibiotics), peptides/proteins (including antibodies) and viruses and bacteria

can be incorporated into liposomes. Water-soluble drugs are trapped in the

aqueous compartment while lipophilic ones are incorporated in the lipid phase

of liposomes. Because of their availability in various sizes, ability to

incorporate both water as well as oil soluble drugs, their inertness and their

ability to protect labile drugs, liposomes are versatile carriers for

parenteral drug delivery systems. Intramuscularly and subcutaneously injected

liposomes deliver drug at a controlled rate while intravenous administration

selectively targets them to reticuloendothelial system and phagocytic cells. A

simple method by which liposomes can be produced involves drying an organic

solvent solution of lipids onto the wall of a flask/beaker followed by

hydration and dispersion of lipid by addition of buffer and mixing (Fig.

14.14).

Fig. 14.14 Production procedure for liposomes.

6. Resealed Erythrocytes

Drug loading in body’s own erythrocytes when used

to serve as controlled delivery systems have several advantages. They are fully biodegradable and biocompatible,

nonimmunogenic, can circulate intravascularly for days (act as circulatory drug

depots) and allow large amounts of drug to be carried. The drug need not be

chemically modified and is protected from immunological detection and enzymatic

inactivation. Drug loading can be done by immersing the cells in buffered

hypotonic solution of drug which causes them to rupture and release hemoglobin

and trap the medicament. On restoration of isotonicity and incubation at 37o

C, the cells reseal and are ready for use (Fig. 14.15).

Fig. 14.46 Drug loading in crythrocytes

Damaged erythrocytes are removed by the liver and

spleen. These organs can thus be specifically targeted by drug loaded

erythrocytes.

B. Implants

An ideal

implantable parenteral system should possess following properties—

1. Environmentally stable : should

not breakdown under the influence of heat, light, air and moisture.

2. Biostable : should not undergo

physicochemical degradation when in contact with biofluids (or drugs).

3. Biocompatible : should neither stimulate immune

responses (otherwise the implant will

be rejected) nor thrombosis and fibrosis formation.

4. Nontoxic and noncarcinogenic : its

degradation products or leached additives must be completely safe.

5. Should have a minimum surface

area, smooth texture and structural characteristics similar to the tissue in

which it is to be implanted to avoid irritation.

6. Should be removable

when required.

7. Should release the medicament at a constant

predetermined rate for a predetermined period of time.

Some of the important advantages of implants over injectable controlled-release

formulations are—

1. More effective and more

prolonged action (for over a year).

2. A significantly small dose is

sufficient.

A major disadvantage

of such systems is that a microsurgery is required for implantation of device.

Some devices can be easily implanted by use of a specially designed implanter

syringe. The devices are generally implanted subcutaneously or intramuscularly.

Subcutaneous tissue is an ideal location because of its easy access to

implantation, poor perfusion, slow drug absorption and low reactivity towards

foreign materials.

The drug may be dissolved, dispersed or embedded in

a matrix of polymers that control release by dissolution, diffusion or both,

bioerosion, biodegradation or an activation process such as osmosis or

hydrolysis. The system is generally prepared as implantable flexible/rigid

moulded or extruded rods, spherical pellets or compressed tablets. Polymers

used are silicone elastomers, polymethacrylates, polycaprolactone,

polylactide/glycolide, etc. Drugs generally presented in such systems are

steroids like contraceptives (megestrol acetate, norgestrone, etc.), morphine

antagonists like naltrexone for opiod-dependent addicts, etc.

C. Infusion Devices

These are also implantable devices but are

versatile in the sense that they are intrinsically powered to release the

medicament at a zero-order rate and the drug reservoir can be replenished from

time to time. Depending upon the mechanism by which these implantable pumps are

powered to release the contents, they are classified into following types:

1. Osmotic pressure activated drug delivery systems

2. Vapor pressure activated drug

delivery systems

3. Battery powered drug delivery

systems

1. Osmotic Pumps (Alzet)

These pumps are capsular in shape and made in a

variety of sizes. The device is shown in Fig. 14.16.

The pump is made of three concentric layers—the

innermost drug reservoir contained in a collapsible impermeable polyester bag

(which is open to the exterior via a single portal) followed by a sleeve of dry

osmotic energy source (sodium chloride) and the outermost rigid,

rate-controlling semipermeable membrane fabricated from substituted cellulosic

polymers. A rigid polymeric plug is used to form a leakproof seal between the

drug reservoir and the semipermeable housing. An additional component, the flow

modulator, comprising of a cap and a tube made of stainless steel is inserted

into the body of osmotic pump after filling. After implantation, water from the

surrounding tissue fluids is imbibed through the semipermeable membrane at a

controlled rate that dissolves the osmogen creating an osmotic pressure

differential across the membrane. The osmotic sleeve thus expands and since the

outer wall is rigid, it squeezes the inner flexible drug reservoir and drug

solution is expelled in a constant volume per unit time fashion. The drug

delivery continues until the reservoir is completely collapsed. Ionized drugs,

macromolecules, steroids and peptides (insulin) can be delivered by such a

device.

Rate Controlling Factors :

Porosity of semipermeable membrane

Osmotic pressure difference across the

membrane

Fig. 14.16 Cross section of osmotic pump

2. Vapour Pressure Powered Pump (Infusaid)

This device is based on the principle that at a

given temperature, a liquid in equilibrium with its vapour phase exerts a

constant pressure that is independent of enclosing volume. The device is shown

in Fig. 14.17.

The disc shaped device consists of two chambers—an

infusate chamber containing the drug solution which is separated by a freely

movable flexible bellow from the vapour chamber containing inexhaustible

vaporizable fluid such as fluorocarbons. After implantation, the volatile

liquid vaporizes at the body temperature and creates a vapour pressure that

compresses the bellows and expels the infusate through a series of flow

regulators at a constant rate. Insulin for diabetics and morphine for

terminally ill cancer patients have been successfully delivered by such a

device.

Fig. 14.17 Cross section of vapor pressure driven device

3. Battery Powered Pumps

Two types of battery powered implantable programmable

pumps used successfully to deliver insulin are—peristaltic pump and solenoid

driven reciprocating pump, both with electronic controls. The systems can be

programmed to deliver drug at desired rates. Their design is such that the drug

moves towards the exit and there is no backflow of the infusate.

Related Topics