Olefin Metathesis

| Home | | Organic Chemistry |Chapter: Organic Chemistry : Carbon-Carbon Bond Formation Between Carbon Nucleophiles and Carbon Electrophiles

In the last 10 years or so an exciting new strategy has emerged for the formation of carbon–carbon double bonds, namely olefin metathesis.

OLEFIN METATHESIS

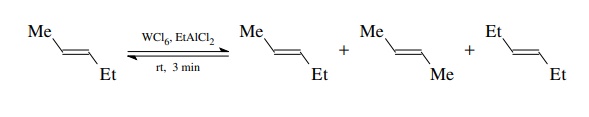

In

the last 10 years or so an exciting new strategy has emerged for the formation

of carbon–carbon double bonds, namely olefin metathesis. This work grew out of

the development of Ziegler–Natta catalysts for the polymerizarion of cyclic

olefins. It was found that when 2-pentene was treated with a catalyst prepared

from tungsten hexachloride and ethylaluminum dichloride, a mixture of

2-pentene, 2-butene, and 3-hexene was produced in minutes at room tempera-ture

(rt)!

It

was shown that the mixture was an equilibrium mixture. Thus it appears that the

alkenes are being broken apart at the double bonds and the pieces reassembled

randomly. This process was termed olefin metathesis because the ends of the

carbon–carbon double bonds are being interchanged.

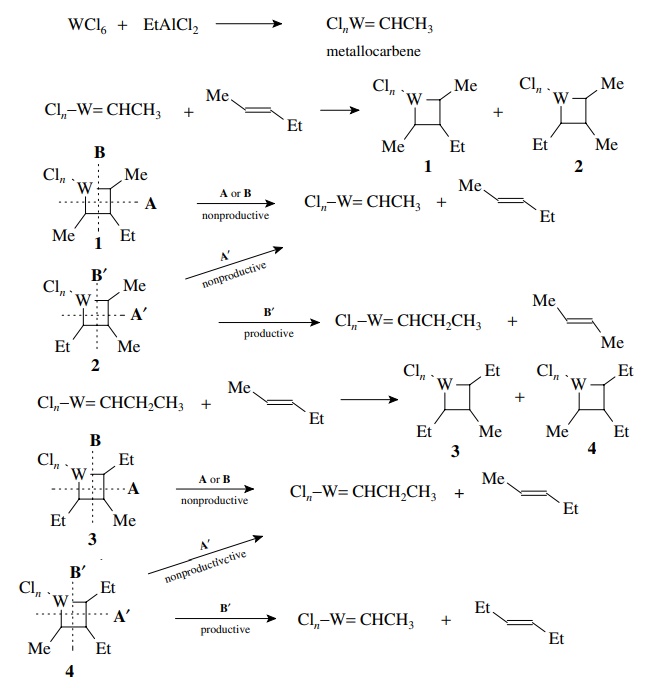

It

was subsequently shown that the active catalytic species is a metallocarbene

complex which contains a carbon–metal double bond. This catalyst undergoes a 2+2 addition with an alkene to give

two metallocyclobutanes 1 and 2 (below) which depend on the regiochemistry

of addition. Metallocyclobutane 1 is

a non-productive intermediate since cleavage across the ring by A or B gives back the reactants. Metallocyclobutane 2 can cleave across the ring A’

to give the original alkene and metallocarbene or it can cleave in the opposite

direction B to give a new alkene and

a new metallocarbene. The new metallocarbene can add the starting material to

give two metallocyclobutanes 3 and 4. It is seen that 3 is a nonproductive intermediate whereas 4 can give another new alkene by cleavage in the B direction. Since each step is

reversible, it can be seen that ultimately the ends of the double bond will be

exchanged to give a mixture of olefins.

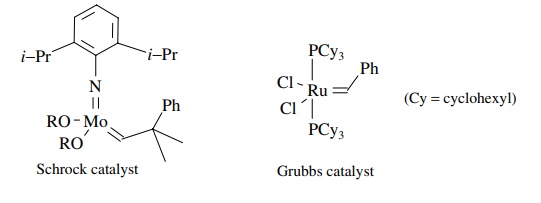

Olefin

metathesis is a unique reaction and is only possible by transition metal

catalysis. In fact only complexes of Mo, W, Re, and Ru are known to cat-alyze

olefin metathesis. Once it was known that metallocarbenes were the actual

catalytic species, a variety of metal carbene complexes were prepared and evalu-ated

as catalysts. Two types of catalysts have emerged as the most useful overall.

The molybdenum-based catalysts developed by Schrock and ruthenium-based

catalysts developed by Grubbs.

Both

are stable metallocarbene complexes, but they have very different reac-tivity

profiles. The molybdenum catalyst is highly reactive and is effective with

sterically demanding olefins. Its drawbacks are that it is not highly tolerant

of diverse functional groups and has high sensitivity to air, moisture, and

solvent impurities. The ruthenium system, on the other hand, is catalytically

active in the presence of water or air, and it exhibits a remarkable functional

group tolerance. It is not a reactive as the molybdenum catalyst, particularly toward

sterically bulky substrates. However, it is readily available and is the

reagent of choice for all but the most difficult substrates.

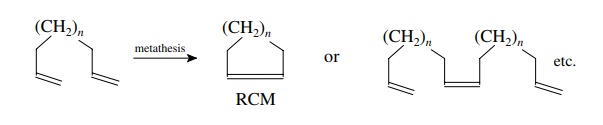

At

present the most synthetically important metathesis process is ring-closing

metathesis (RCM) as it can be used for the preparation of a wide variety of

medium to large ring compounds from acyclic diene precursors. For such dienes

there are two competing processes. The first is RCM, in which the two olefinic

units undergo intramolecular reaction to give a cyclic product. The second is

intermolecular metathesis, which yields open-chain dimers or oligomers.

The

rate of formation of the RCM product is given by a first-order rate law since

the metathesis is intramolecular, rateRCM = k1

[catalyst][diene]. The rate of dimer formation is a second-order rate law

because the reaction is inter-molecular, ratedimer = k2

[catalyst][diene]2. Although these two rate laws are not strictly

comparable because of their different orders, at normal concentrations (0.25–1

M) the difference in rates is mostly due to the difference in the rate

con-stants k1 and k2. Given that the

double-bond energies in five- and six-membered rings are very similar to the

bond energy of an open-chain double bond, the ΔH

±

for the two processes are similar. Thus ΔH± cannot be

responsible for a significant difference in the rates of the two reactions.

The

rate constant k1 for the

RCM process is greater than the dimerization rate constant k2 because of a distinct entropic advantage. In RCM the

two reacting bonds are present in the same molecule and two molecules (the

product and ethylene) are formed from one; thus RCM proceeds with a gain in

entropy. The dimerization process causes loss of translational degrees of

freedom because one molecule is formed from two and thus occurs with a loss of

entropy. As a result the formation of five- and six-membered rings have larger

rate constants and thus proceed at faster rates than dimerization under normal

conditions.

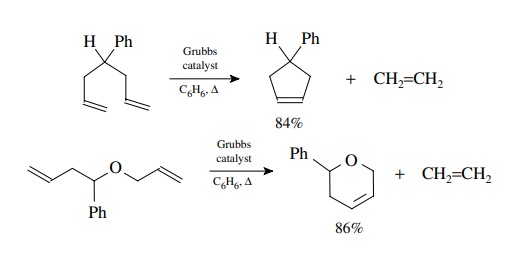

The

use of the Grubbs catalyst is largely restricted to terminal dienes. In these

cases the by-product is ethylene. Since this is an equilibrium process, the

ethylene diffuses out of solution, which helps drive the reaction to

completion. Nevertheless the catalyst is highly tolerant of functional groups

and generally gives good yields.

The

formation of medium rings presents challenges for this and most ring-forming

reactions. There are two major reasons for this. The first is that the molecule

must be able to adopt a reactive conformation in which the two double bonds are

in close proximity for reaction to occur. For larger ring sizes where the

distance between double bonds increases, the population of reactive

conforma-tions decreases so the rate slows as well. The second factor is the

increased ring strain in medium rings which develops at the transition state

and thus raises ΔH± and slows the rate

of the intramolecular process. The rate of the intermolecular dimerization

remains roughly the same. Thus the rate of the intramolecular pro-cess for

medium rings slows dramatically while the dimerization rate remains the same

(for a given concentration).

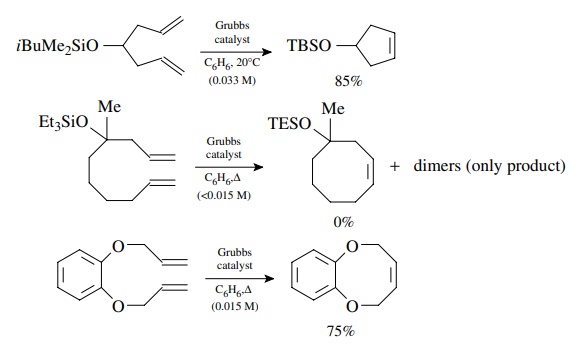

This

behavior is easily demonstrated by the following examples. Formation of a

five-membered ring takes place easily under mild conditions. Formation of a

similar eight-membered ring from an open-chain precursor gave no RCM product but

only dimerization. In contrast bis-allylcatechol gives the eight-membered ring

RCM product efficiently. The phenyl ring provides a conformational constraint

which keeps the olefins in reasonably close proximity and the lack of C–H bonds

in the catechol fragment reduces transannular strain in the eight-membered

ring. These factors allow the RCM to be favored over dimerization.

A

second way to increase the proportion of RCM is to keep the concentration of

the starting diene as low as is feasible. Because dimerization is a

second-order reaction, decreasing the concentration of the diene decreases the

rate of the second-order reaction much faster than the rate of the first-order

RCM reaction decreases. Thus carrying out the reaction at very low

concentrations can actually result in the RCM becoming significantly faster

than dimerization. There are several ways to do this experimentally. The first

is to simply dilute the reaction mixture to the desired concentration and then

run the reaction normally. Although simple, this approach requires a lot of

solvent which must be paid for and then removed. A simpler process is to use

very slow addition of a solution of the diene to a solution of the catalyst. If

the diene reacts as it is added, then the concentration of the diene remains

very low over the course of the addition without having to use large volumes of

solvent to achieve it.

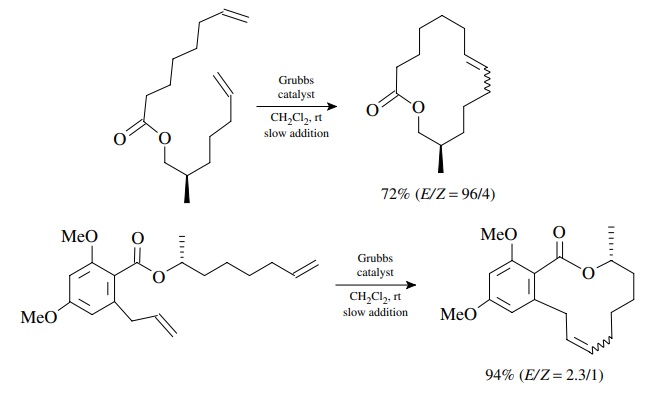

For

large rings where ring strain is again minimal, only the effective

concen-tration of reactive conformers limits the RCM process. In these cases,

running the reaction at high dilution slows the dimerization sufficiently to

allow successful formation of large rings. This is truly a remarkable ability

since large rings are difficult to access by other reactions.

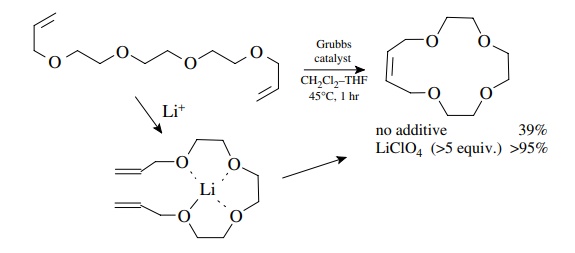

The

effect of conformation on the efficiency of RCM is extremely important. The RCM

of the polyether diene shown below gives only a 39% yield under normal

conditions. Addition of lithium ions to the reaction mixture causes the ether

oxygens to wrap around the lithium cation. This forces the olefinic bonds into

close proximity and the RCM product is now formed in >95% yield. Other structural features such as hydrogen bonding,

restricted rotation (as in amides), or steric effects which cause particular

conformations to be favored are very important in the formation of large ring

systems. Such effects can affect RCM either positively or negatively depending

on whether the olefinic bonds are held proximal or distal to each other.

The

development of RCM has dramatically changed synthetic planning for ring

systems, particularly medium and large ring systems. It represents a new

paradigm for assembling carbon skeletons of ring compounds. Further advances

will only increase its importance as a method for carbon–carbon bond formation.

Related Topics