Free-Radical Initiation

| Home | | Organic Chemistry |Chapter: Organic Chemistry : Carbon-Carbon Bond Formation By Free-Radical Reactions

Besides new insight into the reactivity of free radicals, methods for the production of carbon-centered free radicals have also seen major improvements in the last several years.

FREE-RADICAL INITIATION

Besides

new insight into the reactivity of free radicals, methods for the production of

carbon-centered free radicals have also seen major improvements in the last

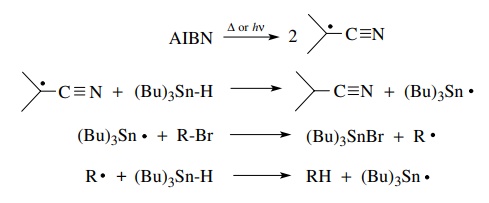

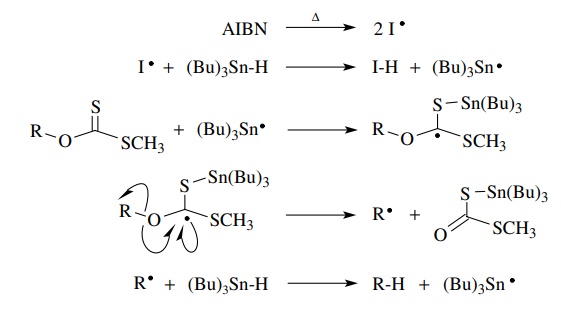

several years. One very common new method is to use tin-based reagents as

radi-cal chain carriers. Trialkyltin radicals readily abstract bromine or

iodine from car-bon to produce a carbon-centered free radical. Placement of a

bromide or iodide substituent on a substrate thus permits formation of a

carbon-centered free radical at that position using tin-based methodology. This

process was initially developed for the reduction of alkyl halides, and it

remains an excellent synthetic method for that purpose. The complete chain

mechanism for the reduction is shown.

One

equivalent of tributyltin hydride is required to reduce one equivalent of alkyl

halide. Each step in the sequence is energetically favored so that side reactions

are minimized. That is, the tributyltin radical does not abstract hydrogen from

the alkyl; it only attacks the halide (Br or I).

Likewise

the carbon radical abstracts the hydrogen from tin much more readily than other

C–H hydrogens. Thus the process is clean from a mechanistic point of view and

consequently leads to clean reduction products.

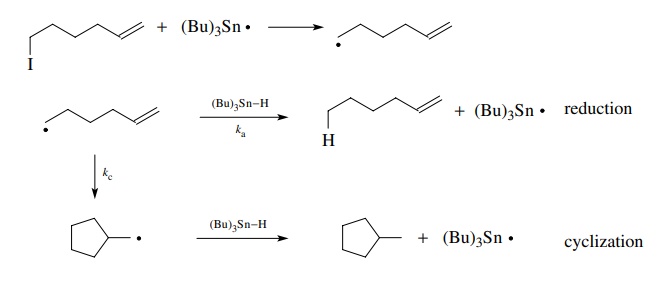

If

this method of free-radical generation is applied to an unsaturated alkyl

halide, the free radical has two pathways available. It can abstract a hydrogen

from tributyltin hydride and give a reduced product as in the reduction process

described above. Alternatively, it can cyclize to give a new cyclic radical

which can abstract hydrogen from tributyltin hydride to give a cyclized product.

These competing propagation steps are shown.

Now

the ratio of products obtained depends on the competing rates of the two

processes. The rate of reduction of the radical is given by ka[R●] [Bu3SnH]

while the rate of cyclization is given by kc[R●].

As was mentioned previously, it has been found that kc is sufficiently large that cyclization is often the

major process. However, reduction is always possible. One way to control

reduction is to note that it is a second-order process which depends on both

the concentration of the radical R● and tributyltin hydride. Thus the rate of

reduction can be lowered simply by running the reaction under dilute

conditions. As the concentration goes down, the rate of reduction goes down

much faster than the rate of cyclization, and cyclization is favored.

After

cyclization has taken place, the only reaction available to the cyclopentyl

methyl radical is hydrogen abstraction. Thus it remains in solution until it

reacts with tributyltin hydride to produce methylcyclopentane and a tributyltin

radical which continues the chain.

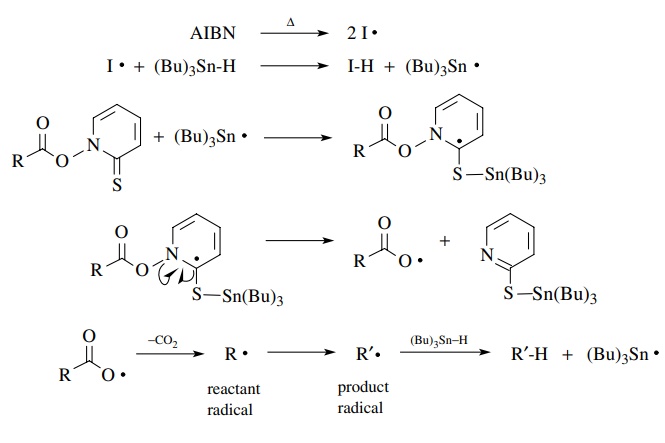

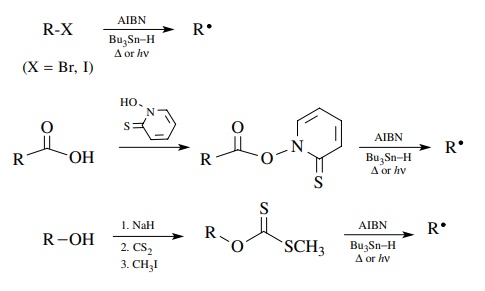

A

second common way to produce free radicals for use in carbon–carbon bond-making

reactions is to use esters of N

-hydroxypyridine-2-thione. This meth-od is also tin based and relies on the

propensity for tin radicals to add to carbon–sulfur double bonds. Subsequent

fragmentation reactions lead to free radicals that are ultimately used in the

propagation steps.

The

free radicals R● participate in a product producing a chain process that

regenerates Bu3Sn● and thus continues the chain. While there are

many steps in this overall sequence, it is a chain process. If each step is

exothermic and kinetically favored, then each step will proceed selectively and

the product will be formed efficiently and reproducibly, irrespective of the

number of the steps in the chain. This turns out to be the case, and the above

method is an effective and reliable sequence for initiating free-radical reactions.

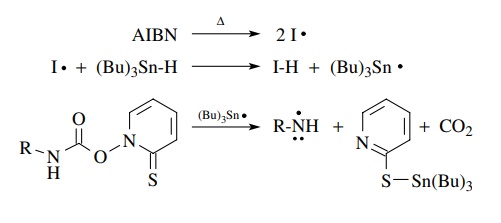

It

is also known that once the tributyltin radical adds to the sulfur of N-hydroxypyridine-2-thione, breakage of

the N–O bond and decarboxylation are very fast and probably concerted. They are

driven energetically by for-mation of the very stable carbon dioxide molecule.

It comes as no surprise that if atoms other than carbon are attached to the

carboxyl group, then they would also end up as free radicals after

decarboxylation. This is shown for a urethane analog as a source of

nitrogen-centered free radicals. A wide variety of other free-radical species

can be produced by this strategy, and it is thus quite useful.

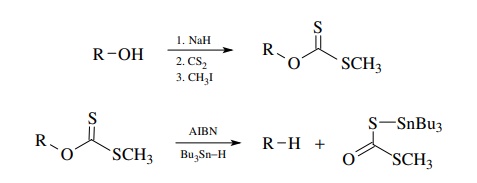

A

third tin-based method of free-radical production also utilizes tin radical

addition to a carbon–sulfur double bond as a key reaction. In this case a

thio-noester (usually a thiono carbonate) is the reactant. As in the previous

method, addition of tin to the sulfur atom is followed by fragmentation to a

carbon-centered radical.

The

driving force for the fragmentation is formation of the C=O double bond. If R● reacts with Bu3SnH,

a tributyltin radical is produced which continues the chain. Carried out in

this manner this reaction is called the Barton deoxygenation of alcohols, since

alcohols are precursors for the thiono esters.

If,

on the other hand, R● is unsaturated and can undergo cyclization rapidly, it

will do so. This competition between reduction of the first formed radical R●

and its cyclization to a new cyclic radical R’● is the same as discussed for

the formation of free radicals from alkyl halides and tributyltin radicals. The

only difference is in the way in which the carbon-centered radical is produced.

A

number of other strategies have been developed for the production of

free-radical intermediates for carbon–carbon bond construction; however, the

tin-based methods described above are by far the most common. Thus alkyl

halides, carboxylic acids, and alcohols are all excellent precursors for free

radi-cals by these methods. The choice of method can be made on the basis of

which substrate fits into the synthetic scheme most efficiently or which

precursor is most readily available.

Related Topics