Fluid Flow

| Home | | Pharmaceutical Technology |Chapter: Pharmaceutical Engineering: Fluid Flow

Fluid flow is an essential element of many pharmaceutical processes.

Fluid Flow

INTRODUCTION

Fluid

flow is an essential element of many pharmaceutical processes. The ability to

propel fluids through pipes and to direct materials from one location to

another is central to the successful manufacture of many products. Fluids

(liq-uids and gases) are a form of matter that cannot achieve equilibrium under

an applied shear stress but deform continuously, or flow, as long as the shear

stress is applied.

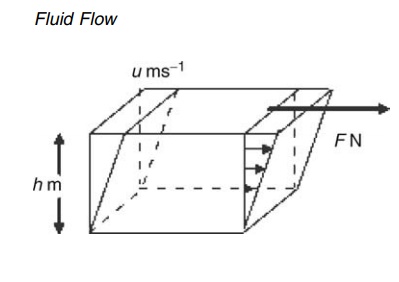

Viscosity

Viscosity

is a property that characterizes the flow behavior of a fluid, reflecting the

resistance to the development of velocity gradients within the fluid. Its

quantitative significance may be explained by reference to Figure 2.1. A fluid

is contained between two parallel planes each of area A m2 and

distance h m apart. The upper plane is subjected to a shear force of F N and

acquires a velocity of u m/sec relative to the lower plane. The shear stress,

t, is F/A N/m2. The velocity gradient or rate of shear is given by u/h or, more generally, by the

differential coefficient du/dy, where

y is a distance measured in a

direction perpendicular to the direction of shear. Since this term is described

by the units velocity divided by a length, it has the dimension T-1

or, in this example, reciprocal seconds. For gases, simple liquids, true

solutions, and dilute disperse systems, the rate of shear is proportional to

the shear stress. These systems are called Newtonian, and we can write

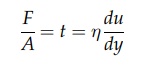

F/A = t = η du/dy (2:1)

The

proportionality constant η is the dynamic viscosity of the fluid: the higher

its value, the lower the rates of shear induced by a given stress. The

dimensions of dynamic viscosity are M L-1 T-1. For the SI

system of units, viscosity is expressed in N·sec/m2. For the

centimeter-gram-second (CGS) sys-tem, the unit of viscosity is poise (P). One

N·sec/m2 is equivalent to 10 P. The viscosity of water at room

temperature is about 0.01 P or 1 centipoise (cP). Pure glycerin at this

temperature has a value of about 14 P. Air has a viscosity of 180 x 10-6

P.

Complex

disperse systems fail to show the proportionality described by equation (2.1),

the viscosity increasing or, more commonly, decreasing with increase in the

rate of shear. Viscosity may also depend on the duration of shear and even on

the previous treatment of the fluids. Such fluids are termed non-Newtonian.

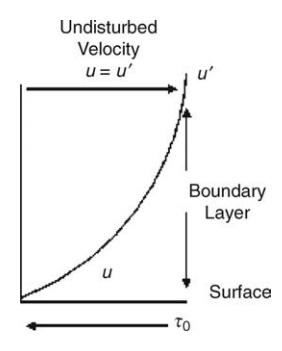

Equation

(2.1) indicated that wherever a velocity gradient is induced within a fluid, a

shear stress will result. When the flow of a fluid parallel to some boundary is

considered, it is assumed that no slip occurs between the boundary and the

fluid, so the fluid molecules adjacent to the surface are at rest (u = 0). As

FIGURE 2.1 Schematic of fluid flow depicting the applied force, velocity in the

direction of motion, and thickness of the fluid.

FIGURE 2.2 Distribution of velocities at a boundary layer.

shown in Figure 2.2,

the velocity gradient du/dy decreases

from a maximum at the boundary (y = 0) to zero at some distance from

the boundary (y = y’) when the velocity

becomes equal to the undisturbed velocity of the fluid (u = u’). The shear stress must, therefore,

increase from zero at this point to a maximum at the boundary. A shear stress,

opposing the motion of the fluid and sometimes called fluid friction, is

therefore developed at the boundary. The region limited by the dimension y’, in which flow of

the fluid is perturbed by the boundary, is called the boundary layer. The

structure of this layer greatly influences the rate at which heat is

transferred from the boundary to the fluid under the influence of temperature

gradient or the rate at which molecules diffuse from the boundary into the

fluid under a concentration gradient. These topics are discussed in chapters 3

and 4.

Compressibility

Deformation

is not only a shear-induced phenomenon. If the stress is applied normally and

uniformly over all boundaries, then fluids, like solids, decrease in volume.

This decrease in volume yields a proportionate increase in density. Liquids can

be regarded as incompressible, and changes of density with pres-sure can be

ignored, with consequent simplification of any analysis. This is not possible

in the study of gases if significant changes in pressure occur.

Surface Tension

Surface

tension, a property confined to a free surface and therefore not applicable to

gases, is derived from unbalanced intermolecular forces near the surface of a

liquid. This may be expressed as the work necessary to increase the surface by

unit area. Although not normally important, it can become so if the free

surface is present in a passage of small-diameter orifice or tube. Capillary

forces, determined by the surface tension and the curvature of the surface, may

then be comparable in magnitude to other forces acting in the fluid. An example

is found in the movement of liquid through the interstices of a bed of porous

solids during drying.

Related Topics