Flow of Fluids Through Packed Beds

| Home | | Pharmaceutical Technology |Chapter: Pharmaceutical Engineering: Fluid Flow

Fluid flow analysis through a permeable bed of solids is widely applied in filtration, leaching, and several other processes.

FLOW OF FLUIDS THROUGH PACKED

BEDS

Fluid

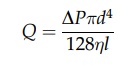

flow analysis through a permeable bed of solids is widely applied in

filtration, leaching, and several other processes. A first approach may be made

by assuming that the interstices of the bed correspond to a large number of

discrete, parallel capillaries. If the flow is streamline, the volumetric flow

rate, Q, is given for a single capillary by equation (2.14),

where

l is the length of the capillary, d, its diameter, ΔP is the pressure drop across the

capillary, and η is the viscosity of the fluid. The length of the capillary

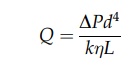

exceeds the depth of the bed of an amount that depends on its tortuosity. The

depth of bed, L, is, however,

proportional to the capillary length, l,

so

where

k is a constant for a particular bed.

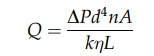

If the area of the bed is A and it contains n capillaries per unit area, the

total flow rate is given by

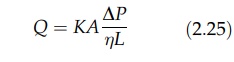

Both

n and d are not normally known. However, they have certain values for a

given bed, so

where

K = d4n/k. This constant is a

permeability coefficient, and 1/K is

the specific resistance. Its value characterizes a particular bed.

The

postulate of discrete capillaries precludes valid comment on the fac-tors that

determine the permeability coefficient. Channels are not discrete but are

interconnected in a random manner. Nevertheless, the resistance to the passage

of fluid must depend on the number and dimensions of the channels. These

quantities can be expressed in terms of the fraction of the bed that is

void—that is, the porosity—and the manner in which the void fraction is

distributed. With reference to a specific example, water would flow more easily

through a bed with a porosity of 40% than through a bed of the same material

with a porosity of 25%. It would also flow more quickly through a bed of coarse

particles than through a bed of fine particles packed to the void fraction or

porosity. The latter effect can be expressed in terms of the surface area

offered to the fluid by the bed. This property is inversely proportional to the

size of the particles forming the bed. Permeability increases as the porosity

increases and the total surface of the bed decreases, and these factors may be

combined to give the hydraulic diameter, d0, of an equivalent channel, defined

by

d0 = Volume of voids / Total

surface of material forming bed

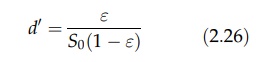

The

volume of voids is the porosity, and the volume of solids is 1 - ε. If the specific surface area, that

is, the surface area of unit volume of solids, is S0, the total

surface presented by unit volume of the bed is S0(1 - ε). Therefore,

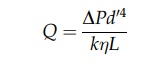

Under

laminar flow conditions, the rate at which a fluid flows through this

equivalent channel is given by equation (2.14) as

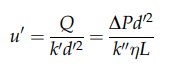

The

velocity, u’, in the channel is

derived by dividing the volumetric flow rate by the area of the channel, k’d’2. Combining the

constants produces,

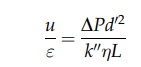

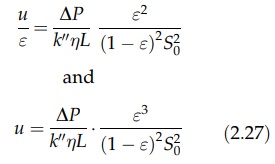

This

velocity, when averaged over the entire area of the bed, solids, and voids,

gives the lower value, u. These

velocities are related by the equation u

= u’e. Therefore,

Substituting

for d’ by means of

equation (2.26) gives

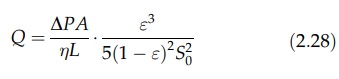

In

this equation, known after its originator as Kozeny’s equation, the constant k’ has a value of 5 ± 0.5. Since Q = uA, where A is the area of the bed,

equation (2.27) can be transformed to

This

analysis shows that permeability is a complex function of porosity and surface

area, the latter being determined by the size distribution and shape of the

particles. The appearance of specific surface in equation (2.28) offers a

method for its measurement and provides the basis of fluid permeation methods

of size analysis. This equation also applies to the studies of filtration.

Related Topics