Emulsification

| Home | | Pharmaceutical Drugs and Dosage | | Pharmaceutical Industrial Management |Chapter: Pharmaceutical Drugs and Dosage: Dosage forms - Emulsions

Emulsification can be facilitated by the following three mechanisms.

Emulsification

Mechanisms of emulsification

Emulsification

can be facilitated by the following three mechanisms:

1.

Reduction of interfacial tension.

2.

Formation of a monomolecular film at the interface that

physically inhibits coalescence of dispersed-phase granules.

3.

Changing the zeta potential of the dispersed phase.

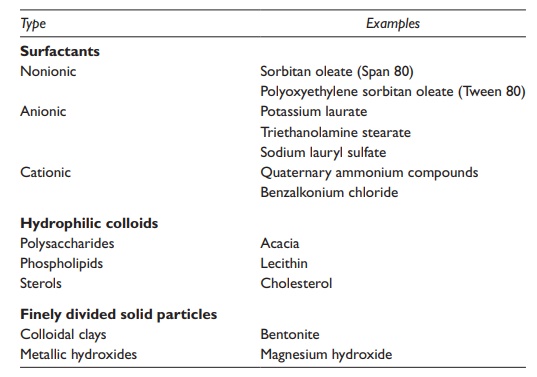

Emulsifying

agents can be surfactants, hydrophilic colloids, or finely divided solid

particles. Table 17.2 lists some of the

commonly used emulsi-fying agents.

Table 17.2 Typical emulsifying agents

Surfactants

Surfactants are amphiphilic molecules, which contain both a polar hydro-philic region and a nonpolar hydrophobic region. Depending on the func-tional groups and relative surface areas of the two regions, surfactants could have a range of hydrophilic and hydrophobic properties. The use of predominantly hydrophilic emulsifying agent leads to the formation of an o/w emulsion since it has stronger and/or greater area of interac-tion with the aqueous than the oily phase. Conversely, the use of a pre-dominantly hydrophobic emulsifying agent tends to form a w/o emulsion because it has stronger and/or greater area of interaction with the oily than the aqueous phase.

Since

the same surfactant molecule has attractive interactions with both the oily and

aqueous phase, surfactants get adsorbed at the oil–water inter-faces to form monomolecular films. This results in a

decrease in interfacial tension and physical barrier to collision of

dispersed-phase globules. Often, simultaneous use of a predominantly

hydrophilic with a predominantly hydrophobic surfactant is used to form more

stable emulsions, due to the close packing, strength, and flexibility of the

interfacial layer. In addition, the use of ionized surfactants can impact the zeta potential of the dispersed phase.

This mechanism can further improve emulsion stability by increas-ing or

decreasing electrostatic repulsive forces and facilitating flocculation.

Ionic and nonionic surfactants

Surfactants

could be anionic (containing anionic, or acidic, functional groups, such as

sulfates and carboxylates that become negatively charged at solution pH higher

than their pKa), cationic

(containing cationic, or basic, functional groups, such as amines that become

positively charged at solu-tion pH higher than their pKa), amphoteric (containing both anionic and cationic

functional groups, with a propensity to become either or both posi-tively and

negatively charged, depending on the pH), and nonionic (without any ionizable

functional groups, such as alcohols). In addition, surfactants that bear a

quaternary ammonium ion bear a permanent positive charge.

Ionized

surfactants tend to have strong and specific interactions with a variety of

molecules and are, consequently, more toxic than nonionic sur-factants.

Nonionic surfactants are less sensitive to variations in the electro-lyte

content and pH of the formulation. Nonionic surfactants, such as the alkyl or

aryl polyoxyethylene ethers, sorbitan polyoxyethylene derivatives, and sorbitan

are widely used for producing stable emulsions.

Hydrophile-lipophile balance value

The

relative hydrophobicity and hydrophilicity of a surfactant is indicated by its

hydrophile–lipophile balance (HLB) value. A typical HLB value scale ranges from

0 to 20. An emulsifying agent with high HLB (~9–12) is pref-erentially soluble

in water and favors the formation of an o/w emulsion. Conversely, surfactants

with low HLB value (~3–6) are preferentially oil soluble and tend to form w/o

emulsions.

The

HLB system assumes the hydrophilic contribution of the surfac-tant from

ionizable and water-miscible functional groups, such as poly-hydric alcohols,

ethylene oxide group, fatty acid, or fatty alcohol groups. The hydrophilic

portion of a molecule is calculated on a molecular weight basis and divided by

5 to arrive at the HLB value. In general, surfactants with an HLB value of 1–3

can be used for mixing oils, 4–6 for making w/o emulsions, 7–9 for wetting

powders into oils, 7–10 for making self-emulsifying systems, 8–16 for making

o/w emulsions, 13–15 for making detergents, and 13–18 for making

self-microemulsifying systems.

Hydrophilic colloids

Hydrophilic

colloids are polymeric materials that bear several electronega-tive atoms, such

as oxygen and nitrogen, thus having strong hydrophilicity through dipole–dipole

interactions and hydrogen bond formation. Several hydrophilic colloids, such as

gelatin, casein, acacia, cellulose derivatives, and alginates, are used as

emulsifying agents. Hydrophilic colloids are used for formation of o/w

emulsions since the films are hydrophilic. These mate-rials adsorb at the

oil–water interface and form multilayer

films around the dispersed droplets of oil in an o/w emulsion. Most

cellulose derivatives are not charged, but can sterically stabilize the

systems.

Hydrated

hydrophilic colloids differ from surfactants because they do not cause an

appreciable lowering in interfacial tension. They stabilize emul-sions by the

formation of multilayer films that are strong and resist coales-cence. In

addition, they increase the viscosity of the dispersion medium.

Finely divided solid particles

Finely

divided solid particles that are wetted to some degree by both oil and water

can act as emulsifying agents by concentrating at the interface, where they

produce a film of particles around the dispersed droplets and act as a physical

barrier to coalescence. Finely divided solid particles that are predominantly

wetted by water form o/w emulsions, whereas those that are predominantly wetted

by oil form w/o emulsions. Examples include bentonite, magnesium hydroxide, and

aluminum hydroxide.