Colon-targeted drug delivery

| Home | | Pharmaceutical Drugs and Dosage | | Pharmaceutical Industrial Management |Chapter: Pharmaceutical Drugs and Dosage: Organ-specific drug delivery

Traditionally, colonic drug delivery is focused on the treatment of local conditions such as ulcerative colitis, colorectal cancer, irritable bowel syndrome, amebiasis, and Crohn’s disease.

Colon-targeted

drug delivery

Traditionally,

colonic drug delivery is focused on the treatment of local conditions such as

ulcerative colitis, colorectal cancer, irritable bowel syndrome, amebiasis, and

Crohn’s disease. However, it has been gaining importance for the systemic

delivery of potent compounds such as proteins, peptides, and oligonucleotides

that are unstable in the harsh conditions of the upper GI tract. As colon is

rich in lymphoid tissues, it offers opportuni-ties for the oral delivery of

vaccines targeted for release and absorption in the lower GI tract. In

addition, colon delivery can be exploited to improve the bioavailability of

drugs that are extensively metabolized by cytochrome P450 enzymes in the upper

GI tract, because the activity of these metabo-lizing enzymes are relatively

lower in the colonic mucosa. Colon-specific drug delivery may also help

overcome GI side effects of drugs. For example, conversion of flurbiprofen to a

glycine prodrug, hydrolysable by colonic microfloral enzymes (amidases),

reduced its ulcerogenic activity in rats. Targeted drug delivery to the colon has been extensively studied.

Colon-specific

drug delivery is challenged by its distal location in the GI tract. Even

localized delivery through the rectum, however, only reaches a small part of

the colon and is not a patient-friendly mode of adminis-tration. Therefore,

oral delivery has been explored, utilizing physiological differences in the

colonic microenvironment and physiology. The aspects of colon physiology that

have been exploited to develop drug-targeting strategies include the presence

of unique colonic microflora, high pH, the relatively predictable transition

time in the small intestine, and high intra-luminal pressure inside the colon.

In addition, osmotically and oxidation potential controlled DDSs, and

bioadhesive polymers have been used for colonic drug delivery.

Utilization of the unique colonic microflora

Human

colonic microflora consists predominantly of bacteria, which also make up to 60%

of the dry mass of feces. The metabolic activities of this microflora results

in the salvage of absorbable nutrients from diet by fermenting unused energy

substrates, trophic effects on the epi-thelium, and protection of the colonized

host against invasion by alien microbes. Colonic bacteria are mostly gram

negative and anaerobic, except cecum, which can have high amount of aerobic

bacteria. Bacteria in the proximal part of the colon are primarily involved in

ferment-ing carbohydrates, whereas the latter part breaks down proteins and

amino acids.

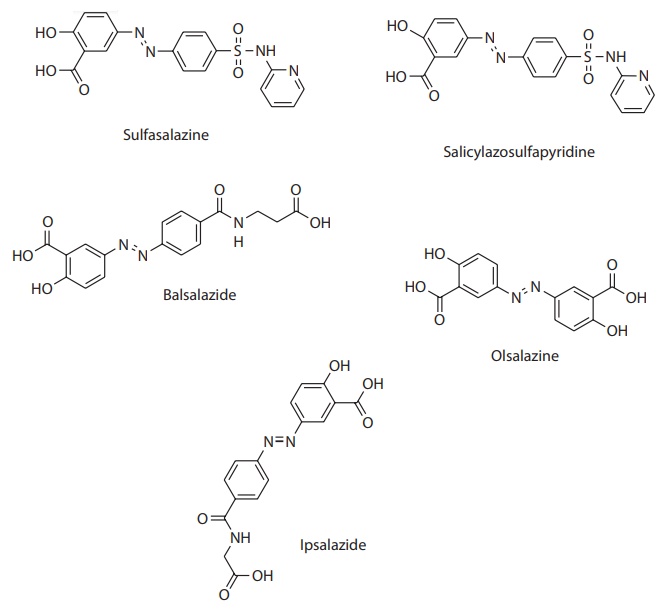

The

unique metabolic ability of these microbes has been exploited to develop

polymerics and prodrugs that are degraded by the unique enzy-matic activities

of colonic microflora. In particular, the azo reductase and glycosidase

activities of the microflora help degrade the azo bound and glycosidic

linkages. Prodrug strategy for colonic drug delivery utilizes drug conjugation

with a promoiety through an azo bond, which is degraded by the colonic

bacteria. Examples of such prodrugs include sulfasalazine, balsalazide,

ipsalazide, olsalazide, and salicylazosulfapyridine for the treatment of

inflammatory bowel disease. As shown in Figure 15.5,

these

Figure 15.5 Colon-targeted drug delivery by prodrug strategy. Prodrug strategy for

colonic drug delivery utilizes drug conjugation with a promoiety through an azo

bond, which is reductively cleaved by the colonic anaerobic bacteria to release

the parent compound. This figure shows the structure of several prodrugs of

5-amino salicylic acid (5-ASA), an anti-inflammatory compound used for the

treatment of inflammatory bowel disease.

Sulfasalazine was first introduced for the treatment of rheumatoid

arthritis and inflammatory bowel disease. In the colon, it degrades into 5-ASA

and sulfapyridine, which is responsible for most of the side effects of

sulfasalazine. This problem was overcome by the use of other promoieties, such

as 4-amino benzoyl glycine in ipsalazine and 4-aminobenzoyl-β-alanine in balsalazide, or azo bond

conjugation of sul-fasalazine with itself to form olsalazine. In addition, the

drug has been covalently conjugated to a polymeric backbone of

polysulfonamidoethylene by azo bond (Figure 15.5).

Polymers

that degrade specifically in the colon have been used for drug targeting by

surface coating to form a barrier to drug release or as matrix systems

embedding the drug substance. For example, azo-linked acrylate copolymers and

poly(ester-ether) copolymers have been used for the delivery of protein and

peptide drugs, and small molecular weight compounds such as ibuprofen, sulfasalazine,

and betamethasone. For embedding the drug in polymer matrices, natural

polysaccharides have been used in oral solid dosage forms to protect the drug

during GI transit and release in the colon on polymer degradation by the

microflora. They offer advantages such as the presence of derivatizable

functional groups and a range of molecular size, in addition to their low

toxicity. The hydrogel (hydrophilic and swelling) prop-erties of these

polymers, however, can lead to the dosage form swelling and disintegration in

the presence of water before reaching the colon. Therefore, these dosage forms

require protection from the aqueous environment during upper GI transit. This

is usually accomplished by the use of protective surface coating or chemical

cross-linking with linkers that are degraded in the colon. Polymers that are

stable in the upper GI tract and degraded by colonic micro-flora include azo

cross-linked synthetic polymers and plant polysaccharides, such as amylose,

pectin, inulin, and guar gum.

A

disadvantage of polymeric coating or embedding approaches for colonic drug

delivery is their dependence on the bacterial microflora in the large

intestine. Although the microflora is fairly constant in the healthy

population, it can be affected by the dietary fermentation precursors, type of

diet consumed, and coadministration of antibiotics. In addition, the nat-ural

polymers are often not available in pure form, which can lead to

physi-cochemical incompatibility with the drug substance and/or inconsistency of

product performance.

pH-dependent dosage forms

pH-sensitive

polymers have been widely used for enteric coating of dosage forms to

facilitate pH-dependent drug release. As the pH increases progres-sively from

stomach (pH 1–2) to small intestine (pH 6–7), and the distal ileum (pH 7–8),

dosage forms can be coated with polymers that dissolve only the aforementioned

specific pH ranges. For colon targeting, the poly-meric coating should be able

to withstand the acidic pH of the stomach and higher pH of the proximal small

intestine, but dissolve in the neutral to slightly basic pH of the terminal

ileum. However, most of the commonly used enteric coating polymeric systems

have a pH threshold of 6.0 or lower for dissolution. These include the

methacrylic acid/methyl methacrylate copolymers, (Eudragits® L100, L-30D,

L100-55), polyvinylacetate phthal-ate (PVAP), hydroxypropyl methylcellulose

phthalate (HPMCP), cellulose acetate phthalate (CAP), and cellulose acetate

trimelliate (CAT). Only Eudragit® S100 and FS 30D have a higher pH threshold of

6.8 and 7.0, respectively.

Eudragit®

S100 coating is used, for example, in the mesalamine (Asacol®, Procter

&Gamble)-delayed release tablets for topical anti-inflammatory action in

the colon. Eudragit® L100 and S100 are copolymers of meth-acrylic acid and

methyl methacrylate with the ratio of carboxyl to ester groups of 1:1 or 1:2,

respectively. The carboxylate groups form salts, lead-ing to polymer

dissolution at basic pH. Drug release from these acrylate polymers also depend on

the plasticizer, nature of the salt in the dissolu-tion medium, and

permeability of the film. Colon-targeted dosage forms utilizing methacrylate

resins for coating or matrix formation have been reported in several molecules

such as bisacodyl, indomethacin, 5-FU, and budesonide.

The

use of pH trigger for drug delivery to the colon, however, has the disadvantage

of inconsistency in dissolution of the polymer at the desired site due to

inter- and intraindividual pH variation, among other factors. For example,

Ashford et al. observed significant variability in the disintegration time and

location of Eudragit® S coated tablets in human volunteers. In addition, based

on GI motility, polymer dissolution can complete toward the end of the ileum or

deep in the colon. In addition, factors such as the presence of short-chain

fatty acids and residues of bile acids in the luminal contents, and the locally

formed fermentation products can reduce the local pH, thus influencing the drug

release mechanism.

Time-dependent drug release

Human

small intestinal transit time for pharmaceutical dosage forms was measured

using gamma scintigraphy and found to be about 3–4 h. Although the transit time

does vary with the amount of food and the type of dosage form, it is less

variable than the gastric emptying time. Timed release of dosage forms to

target the colon are, thus, typically formulated to prevent drug release in the

acidic gastric environment and to prevent the release of drug until 3–4 s after

leaving the acidic gastric environment.

An

example of such timed-release dosage form is the Pulsincap® device. In this

device, the drug formulation is sealed in an impermeable capsule body with a

hydrogel polymer plug. The hard gelatin capsule body may be made insoluble by

exposure to formaldehyde vapor, which cross-links gelatin. The plug expands in

the aqueous GI tract fluid and exits the body, thus releasing drug, after a

time delay determined by the rate of expansion and the length of the plug.

Another

approach utilized a three-layer coated dosage form with an inner coating of an

acid-soluble polymer, Eudragit® E; followed by a water-soluble coat, and the

outer enteric coating of Eudragit® L. An organic acid (succinic acid) was used

as a part of the formulation. On oral administra-tion, the dosage form is

protected in the acidic gastric environment by the enteric coating. In

intestinal conditions, water ingress into the formulation lowers the pH inside

the dosage form by the dissolution of the organic acid.

This,

in turn, causes the inner, acid-labile coat to dissolve, thus releasing the

drug. Drug release rate and lag time is controlled by the coating thickness of

the acid-soluble layer and the amount of organic acid in the formulation. Using

this approach, Fukui et al. prepared timed-release press-coated tablets with

the core tablets containing diltiazem hydrochloride (DIL) and the outer, water

soluble, layer containing phenylpropanolamine hydrochlo-ride (PPA), as a marker

for gastric emptying time. On administration to beagle dogs, the gastric

emptying time and lag time after gastric empty-ing were evaluated by

determining the times at which PPA and DIL first appeared in the plasma, which

were about 4 and 7 h, respectively. The 3 h lag time between the time of

appearance of these drugs in the plasma correlated well with the expected

intestinal transit time.

An

inherent limitation of the time-dependent drug release systems inter-and

intraindividual variability in gastric emptying, and small intestinal and

colonic transit time. This can result in variations in the site of drug release

in the small intestine or within the colon, which can impact drug absorp-tion

as absorption by the transcellular route diminishes in the distal colon.

Osmotically controlled drug delivery systems

Osmotic

DDSs, such as the OROS-CT® system of Alza Corporation, are based on the

incorporation of an osmotic agent, such as a salt, in the dos-age form. The

dosage form is encapsulated in a semipermeable membrane with an orifice for

drug release. On ingestion, osmotic pressure gradient forces the ingress of

water, which leads to the formation of flowable gel in the drug compartment and

generates pressure to force the drug gel out of the orifice at a controlled

rate. Amount of the osmotic agent, rate of water permeation, and size of the

laser-drilled orifice primarily determine the drug release rate. The release

rate can be extended for 4–24 h in the colon and the each osmotic unit is

designed for a 3–4 hpostgastric delay for drug release.

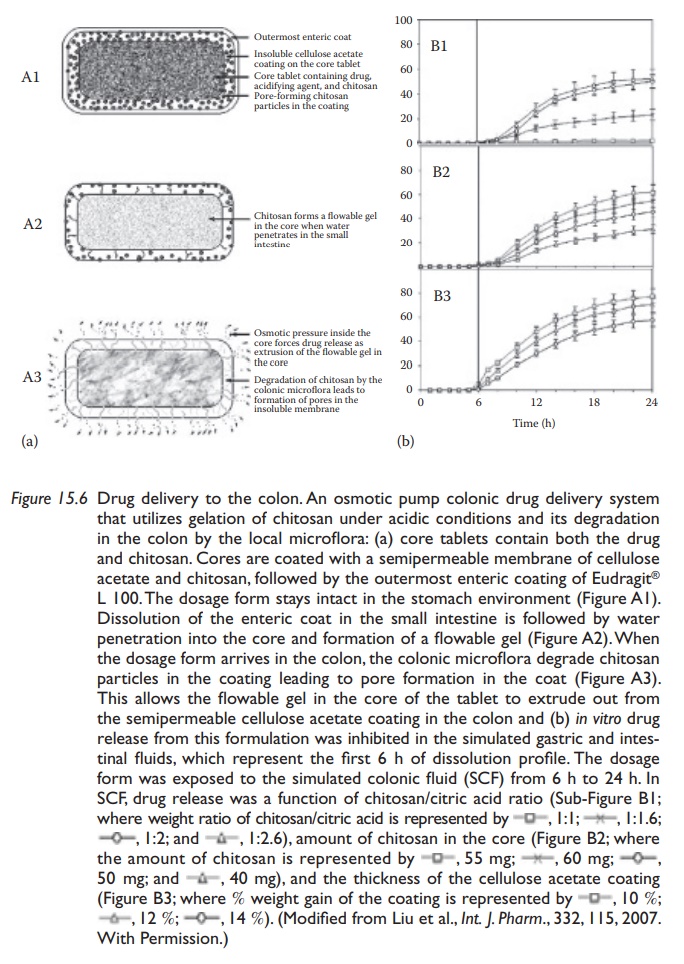

A

modification of the osmotic pump suitable for colonic drug delivery involves

microbially triggered release mechanism. Liu et al. exploited the gelation of

chitosan under acidic conditions and its degradation in the colon to use it as

an osmotic agent and as a pore-forming agent in the impermeable cellulose

acetate membrane. The authors designed a

dosage form containing citric acid and chitosan in the drug containing core,

which had a coating of cellulose acetate and chitosan, followed by an enteric

coat of methacrylic acid/ methyl methacrylate copolymer, Eudragit® L100. As

shown in Figure 15.6a, on reaching the small

intestine, the enteric coat dissolves followed by water permeation into the

core, leading to the formation of a flowable gel through dissolution of citric

acid and swelling of chitosan. However, chitosan in the cellulose acetate

membrane is completely dissolved only in the colonic microenvironment, thus

preventing significant drug release until the dos-age form reaches the colon. Figure 15.6b shows drug (budesonide, used as a model

drug)-release inhibition at gastric and intestinal pH and controlled

Figure 15.6 Drug delivery to the colon. An osmotic pump colonic drug delivery system that utilizes gelation of chitosan under acidic conditions and its degradation in the colon by the local microflora: (a) core tablets contain both the drug and chitosan. Cores are coated with a semipermeable membrane of cellulose acetate and chitosan, followed by the outermost enteric coating of Eudragit® L 100. The dosage form stays intact in the stomach environment (Figure A1). Dissolution of the enteric coat in the small intestine is followed by water penetration into the core and formation of a flowable gel (Figure A2). When the dosage form arrives in the colon, the colonic microflora degrade chitosan particles in the coating leading to pore formation in the coat (Figure A3). This allows the flowable gel in the core of the tablet to extrude out from the semipermeable cellulose acetate coating in the colon and (b) in vitro drug release from this formulation was inhibited in the simulated gastric and intes-tinal fluids, which represent the first 6 h of dissolution profile.

Related Topics